Key Takeaways

- Most fleets still rely on school bus diesel, but gasoline, propane and electric school buses are rapidly expanding.

- Emission controls, DEF and school bus turbo technology have improved air quality compared with legacy diesel bus models

- Electric school bus and propane busses options can reduce school bus exhaust exposure for children.

- Accurate data on diesel school bus mpg, routes and incentives guides smart fuel choices.

- National programs such as EPA Clean School Bus Program support cleaner fleet transitions.

Table of Contents

Are School Buses Diesel?

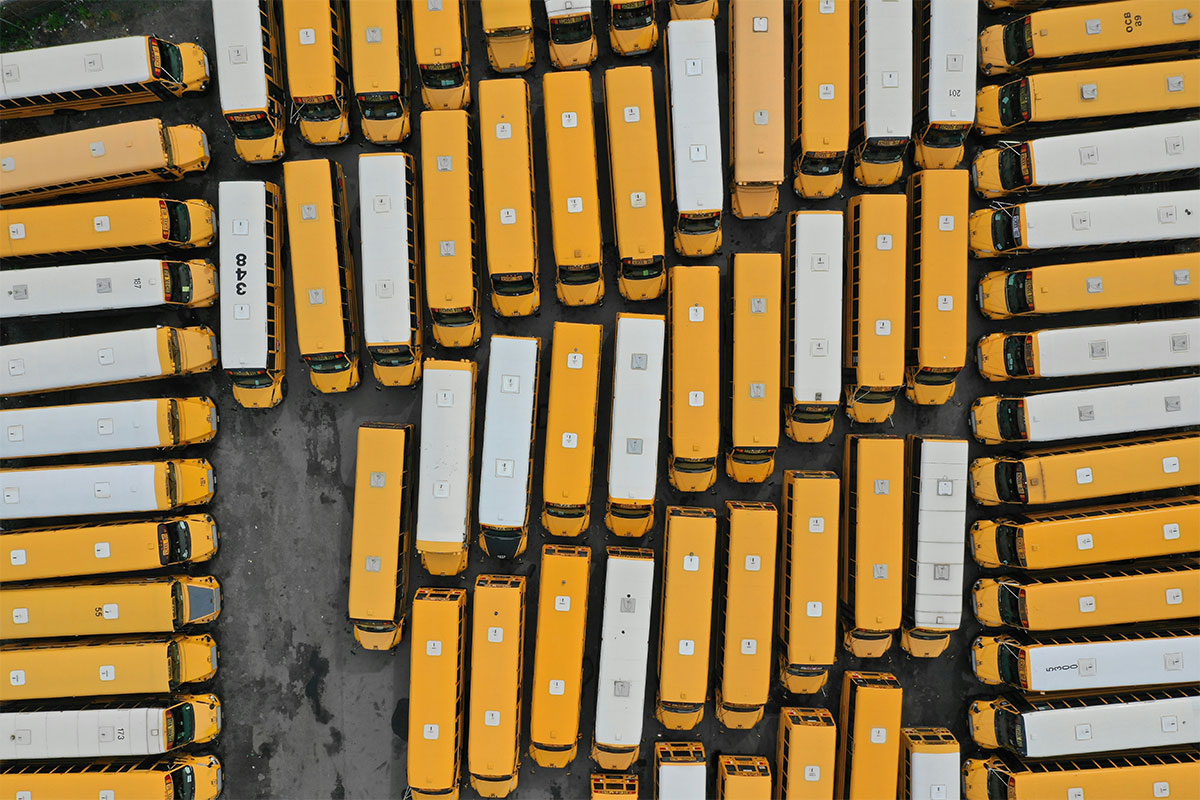

Historically, most North American school bus fleets relied on diesel fuel. Diesel offers high torque, good durability, and low operating costs per mile. Today, diesel remains the answer for many routes, but districts increasingly utilize a mix of diesel, gasoline, electric, and propane options. Policies, incentives, and climate goals strongly influence these choices.

Rural areas often maintain diesel fleets for covering long distances. Conversely, urban districts frequently pilot electric school bus routes. Funding from programs like the EPA Clean School Bus Program and DOE Alternative Fuels Data Center encourages transitioning away from older diesel technologies. District leaders now review data on gasoline versus diesel school buses and consider health impacts when updating transportation plans.

Where Do School Buses Get Fuel?

Most fleets fuel at secure depots with bulk school bus diesel, gasoline or propane busses storage for cost control and safety. Some use public stations, especially for diesel bus or gasoline units, while electric school buses rely on depot chargers. Mobile tankers support remote routes. Fueling choices affect uptime, planning and eligibility for federal clean electric bus school incentives programs.

How Are School Bus Fleets Managed During Weather Delays Or Closures?

During school closures or delays dispatchers manage diesel supplies protect electric charging schedules and plan preventive maintenance. Idle periods allow inspection of exhaust systems checking DEF levels and interior cleaning. Reliable communication informs families about bus operations. Fleet software accurately tracks the readiness of diesel gasoline and electric buses.

How Much Does A Diesel School Bus Cost?

| Bus type | Typical cost range (USD) | Notes |

|---|---|---|

| New diesel school bus | 120000-180000 | Durable, widely available, higher school bus exhaust emissions |

| New gasoline bus | 110000-150000 | Lower upfront than diesel bus, less torque for hilly routes. |

| New electric school bus | 350000-450000 | High upfront, lower fuel, incentives from EPA Clean School Bus. |

| New propane bus | 120000-150000 | Cleaner than older school bus diesel, quieter, relies on propane busses infrastructure. |

| Used school bus diesel | 30000-90000 | Check engine hours, diesel fumes health effects, retrofit options. |

Unsure Which Fuel Best Fits Your School Fleet?

Balancing student health, emissions rules, and tight transport budgets is complex. We’ll help you compare diesel, gasoline, propane, and electric options using real-world cost, mpg, and incentive data tailored to your routes.

Should You Choose A Diesel Or Gas Bus For Your School Fleet?

- Evaluate route length. Long rural trips favor diesel school bus torque and efficiency.

- Compare fuel access. Where depot school bus diesel is limited, gasoline may simplify logistics.

- Review lifecycle cost. Include diesel school bus mpg, maintenance and expected rebuild intervals.

- Consider students’ health. Cleaner engines and lower school bus exhaust reduce exposure.

- Plan future transition. Models compatible with electric school buses or do school buses run on propane strategies ease upgrades.

- Use consultation support from ElanFuels to interpret gas vs diesel school bus data and align funding, incentives and emission goals.

- Assess cold weather and terrain impacts, diesel bus vs gas bus reliability, and training for fueling and school bus cleaning supplies management.

What Engine Does A School Bus Have?

American school buses typically utilize medium duty engines from manufacturers like Cummins and Navistar. A diesel bus usually provides 200-300 horsepower with strong torque for demanding routes. Gasoline and propane buses use similar sized engines but with different fuel delivery systems. Electric school buses are increasingly common and employ battery electric drivetrains with electric motors instead of traditional exhaust systems. Districts should select the appropriate engine by matching its power output to the area’s terrain, climate, passenger capacity, and efficiency goals. Newer emission standards significantly reduce diesel fumes impacting students and communities. Modern designs often include advanced aftertreatment and DEF systems to manage pollution.

Want To Cut Diesel Emissions Without Replacing Every Bus?

From DEF and retrofits to anti-idling policies and telematics, there are practical ways to clean up existing diesel fleets fast. See which upgrades deliver measurable health and compliance benefits first.

Do School Buses Have DEF?

Many modern diesel school buses built after 2010 use Diesel Exhaust Fluid or DEF. This fluid is part of selective catalytic reduction systems. DEF reduces nitrogen oxides in the exhaust, helping these buses meet stricter EPA standards. This technology offers emission benefits similar to electric school buses. Fleet managers must train drivers to monitor the DEF tank level and prevent fluid contamination. Proper DEF use is a cost effective method to reduce diesel fume health risks while districts plan for future electrification.

Do School Buses Have Turbos?

Modern diesel school buses often utilize turbochargers to boost power improve altitude performance and increase efficiency. A turbo enables a fully loaded bus to climb inclines without strain while reducing fuel consumption. Combined with charge air cooling and aftertreatment turbos also help achieve cleaner exhaust. Gasoline and propane units may use naturally aspirated or turbocharged designs. Electric school bus drivetrains deliver instant torque without turbo hardware. Regular inspection of boost leaks lubrication and filters maintains reliability and controls costs.

Do School Buses Run On Propane?

Many school districts utilize school buses that run on propane, finding them particularly suitable for routes with frequent stops. Propane offers several advantages: reliable starting in cold weather, quieter operation compared to diesel, and reduced levels of certain pollutants in the exhaust. Fueling involves dedicated tanks and requires trained personnel, often in partnership with local propane suppliers. Operationally, propane can be cost-competitive with diesel, especially when incentives are factored in; however, effective infrastructure and route planning are essential. While propane does not eliminate emissions entirely, some districts integrate it alongside electric school bus pilot programs. The decision to adopt propane must involve a thorough evaluation of the total cost of ownership, adherence to safety codes, and maintenance capacity. Resources like the DOE Alternative Fuels Data Center tools and manufacturer guidance should be consulted for an objective comparison of performance, range, and refueling needs.

What Is An Electric School Bus?

An electric school bus operates using battery packs and electric motors instead of traditional diesel or gasoline engines. Charging typically occurs at bus depots overnight with managed load strategies. These buses produce zero tailpipe emissions during operation. This greatly improves air quality for students both near stops and inside the bus.

Electric buses generally have lower energy use per mile than diesel buses across various routes. Maintenance requirements are also reduced because there is no need for oil changes exhaust aftertreatment systems or complex transmissions. Higher purchase prices are often offset by incentives from the EPA Clean School Bus Program and state agencies. Proper route selection and charging infrastructure design are essential for dependable service. School districts report quieter operation predictable fueling costs and significant community health benefits.

Ready To Explore Electric & Propane Buses With Real Numbers?

Incentives, charging, propane infrastructure, and lifecycle costs can be confusing. Get a clear, data-backed roadmap for piloting cleaner buses that match your routes, climate, and funding.

Benefit Of Electric School Buses

The most important benefits of electric school buses include zero tailpipe emissions and cutting diesel fumes and health effects near schools and homes. Quieter rides improve comfort inside the school bus and in neighborhoods. Lower fueling and maintenance costs stabilize budgets. EPA Clean School Bus Program support and utility partnerships reduce barriers, helping districts shift from school bus diesel toward healthier, resilient transportation systems.

Who Makes Electric School Buses?

Leading manufacturers in the electric school bus market are Blue Bird, Lion Electric, Thomas Built Buses, and IC Bus. Their offerings include electric school bus models in both Type C and Type D classifications, with varying specifications for range, charging speed, and passenger seating. When purchasing, school districts ought to evaluate warranties, dealer networks, and eligibility for funding from the EPA’s Clean School Bus program as well as various state-level initiatives.

How Much Gas Does A School Bus Use?

Fuel consumption for a school bus varies based on route length idling time and the vehicle’s gas mileage. A large diesel bus traveling 60 miles might consume 6 to 8 gallons averaging 8 to 10 miles per gallon. Gasoline units typically use slightly more fuel. Annual fuel usage multiplied across entire fleets makes tracking school bus gas consumption essential for budget planning and emissions reporting.

Using telematics and detailed fuel logs helps identify excessive idling abnormal exhaust emissions and route inefficiencies. Optimizing routes and selecting the correct bus size reduce overall diesel demand. Furthermore adopting electrification exploring propane options and improving driver training can lower the fuel used per student while maintaining safe and timely service throughout the year.

What Is The Gas Mileage Of A School Bus?

Conventional diesel school bus mpg often ranges from 6-10, depending on load, terrain and idling. Gasoline units can be slightly lower. Alternative fuels and electric school buses express efficiency differently, often in energy per mile. Using DOE data and fleet logs when asking what is the gas mileage of a school bus helps set realistic expectations for planning.

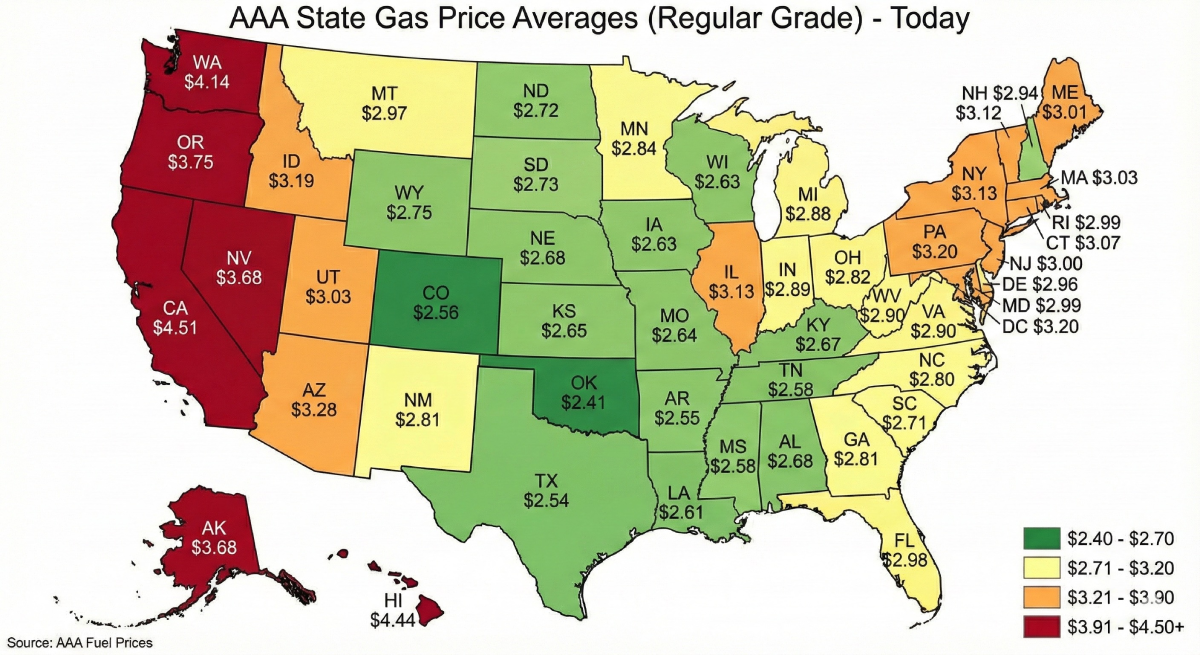

How Much Does It Cost To Fuel A School Bus?

Fuel cost depends on local prices, diesel school bus mpg and annual mileage. A bus running 12000miles at 8mpg uses 1500 gallons. At $4 school bus diesel, this equals $6000 every year. Gasoline and propane buses vary, while electric school bus charging can lead to lower costs.

How Can We Reduce Diesel Emissions From School Buses?

- Install retrofit particulate filters and SCR on older school bus diesel units to clean school bus exhaust.

- Enforce anti idling policies near schools to limit diesel fumes health effects on children.

- Upgrade routing to reduce unnecessary miles and diesel bus fuel burn.

- Use high quality fuels, regular maintenance and school bus cleaning routines for seals and vents.

- Apply to EPA Clean School Bus Program funding to replace aging buses with electric school buses or do school buses run on propane models.

- Educate drivers and technicians on practical steps that reduce diesel truck pollution without compromising safety.

- Partner with experts like ElanFuels for audits, telematics review and long term emissions strategy development and implementation.

Diesel Exhaust, School Buses And Children’s Health

Research confirms that diesel fumes negatively affect health. Effects include aggravated asthma, respiratory irritation, and long term cardiovascular risks especially for children. Older school bus diesel models with uncontrolled exhaust can increase exposure levels both inside and around the buses. The EPA, the UCS, and medical organizations stress that preventing children’s exposure near idling lines is possible. Using cleaner engines, installing retrofits, and implementing electric school buses significantly reduces pollutants. School districts should monitor air quality inside and outside vehicles. They must also engage parents transparently and prioritize routes that serve vulnerable communities. Reducing pollution from diesel truck fleets protects student health. It also ensures transportation plans meet public health goals. Use data from the American Lung Association and EPA to make evidence based decisions for route planning. Regular reviews guarantee that all improvements are measurable, documented, and properly communicated.

Why Should We Transition To Electric School Buses?

Replacing diesel school buses with electric models reduces greenhouse gases and eliminates tailpipe exhaust. This directly improves health outcomes for students drivers and people living nearby by reducing exposure to diesel fumes. Electric buses also operate quietly lowering noise pollution around schools. Maintenance requirements are typically lower. Federal grants and utility support are making the lifetime cost competitive with diesel ownership. Electrification supports district sustainability goals and resilience planning. Using electric buses on established routes with renewable energy maximizes environmental and operational benefits. Acting now allows districts to secure incentives and demonstrate leadership in transportation focused on student wellbeing. Using data tools informs decisions about range charging and infrastructure.