Key Takeaways

- Fuel inventory management ensures accuracy, compliance, and cost savings across industries.

- Automated fuel inventory management software reduces errors and streamlines reconciliation.

- Fuel stock management systems benefit bulk facilities and retail stations.

- Fuel truck inventory tracking prevents losses and discrepancies during delivery.

- Data analytics and monitoring optimize efficiency and forecasting accuracy.

Table of Contents

Fuel Inventory Management

The process of monitoring, controlling and evaluating fuel stocks by recording inflows, tracking the use and reconciling differences in accordance with regulations is fuel inventory management. The goal of tracking the buying and consumption of fuel in a business is to reduce waste, improve accountability and boost profit margins.

For different industries, fuel inventory management has different roles it plays;

- In logistics and trucking, it helps vehicles to not waste a lot of time while serving customers

- In retailing of fuel, it prevents shortages that can frustrate customers

- In energy companies, it helps to assure regulatory alignment and tax compliance.

In the past, many businesses kept their inventory manually but now, businesses and their owners implement automatic solutions that provide remote monitoring that permits business managers to have a full view of stocks, deliveries and consumption patterns. With this data gotten from fuel inventory management, you can make data-driven decisions that lead to profit growth and increased efficiency. For a business seeking to curb waste, save cost and improve operational control growing inefficiency, a fuel management system is a must-have.

Fuel Inventory Management Software

Fuel inventory software seeks to automate recording and analyzing fuel stock data. The main features are real time tank monitoring, automated alerts for significant changes and reporting functions that can be customized to fit business needs.

Fuel inventory management software also has the ability to integrate with other software that do enterprise resource planning, manage fleets and monitor compliance. This permits the business to include fuel tracking solutions into an ecosystem of tools that make business easier to run.

Fuel inventory management software also permits data collection, reporting and reconciliation of data to be less error prone through automation. After implementing automatic monitoring, it’s easier to identify when consumption of fuel is unusual when it is being tracked automatically.

Fuel inventory management software permits easy and efficient tracking alongside seamless data access for teams to be at the same level of information in real time.

Struggling With Fuel Tracking Accuracy?

Manual logs cause errors and waste. Automated fuel inventory management ensures accuracy, accountability, and cost savings across industries.

Fuel Stock Management Systems

For real time visibility and control on stock levels in bulk facilities, airports, marine terminals and fuelling stations, fuel stock management systems are very important. These systems involve fuel monitoring fuel inventory with sensors and automated measurement tools.

As a manager, you can track inflows during delivery, monitor fuel consumption during operations and set limits that will trigger alarms when they are reached. This prevents surprises when stock runs out and reduces the possibility of overfilling.

For filling stations, fuel stick management systems are integrated with point of sale solutions so that data from sales and stock are synchronised. For bulk facilities, these systems help them comply with strict reporting rules thereby reducing the risks of penalties. With the right fuel stick management system, every drop of fuel is accounted for thereby minimizing losses from carelessness and reduces operational costs.

Fuel Truck Inventory Tracking

To make sure the amount of fuel dispatched matches the amount of fuel delivered, businesses use fuel truck inventory tracking to monitor fuel quantities during transportation. These controls avoid financial loss and make sure there’s accounts.

Modern fuel inventory tracking solutions use sensors and GPS-enabled devices to record quantities loaded and unloaded. The data is transmitted in real time to centralized dashboards where managers can compare scheduled deliveries with actual volumes.

With these processes, drivers, customers and suppliers remain transparent. In industries like mining or lengthy hauling it is indispensable to have fuel truck inventory tracking in order to reconcile in transit-stock and prevent theft.

Effective transit tracking builds trust with customers and promotes contractual and regulatory compliance.

What Are The Key Principles Of Fuel Inventory Management?

Fuel inventory management has three core principles, they are as follows;

- Accuracy: Ensures all inflows and outflows are measured correctly, preventing costly discrepancies

- Timelines: Involves uploading records in real time, enabling quick decision-making and efficient procurement planning

- Compliance: Guarantees that businesses meet safety, tax and environmental regulations.

Without these principles, even advanced fuel inventory systems might produce faulty results. So businesses combine both in order to maintain reliability in operations and to reduce costs.

What Is A Fuel Management Plan?

A fuel management plan is a structured plan that sets the path for how a business would procure, use and replenish fuel. It includes:

- Procurement strategies

- Storage and monitoring policies

- Usage guidelines

- Reconciliation procedures

- Safety and compliance protocols

Fuel inventory software is used to align operations with organizational goals. By documenting procedures and assigning responsibilities, businesses prevent mismanagement and create accountability.

A good fuel management plan ensures resources are used efficiently, costs remain under control and everyone remains accountable.

Want Real-Time Visibility of Fuel Stocks?

With advanced tank monitoring and GPS-enabled truck tracking, you’ll know every drop in motion or storage instantly.

How To Reconcile Fuel Inventory?

Reconciling fuel inventory management systems is the process of comparing physical stock levels with recorded data. With this process, accuracy is assured, discrepancies are caught early and fraud is prevented. The steps of reconciliation include;

- Measuring actual tank levels

- Comparing against system or software records

- Investigating differences

- Adjusting entries or conducting audits

With fuel inventory tracking solutions, reconciliation is made easier as automated recording supplies real-time data. Reconciliation is the linchpin for compliance adherence and avoiding regulatory setbacks.

How To Stockpile Fuel?

When stockpiling fuel safety and compliance standards must be top of mind and the reserves have to follow certain rules such as

- Fuel needs to be stored in certified tanks

- Ventilation and fire suppression systems must be available and maintained

- Environmental regulations from organizations such as the EPA must be respected.

Fuel stock management systems help keep fuel usable by tracking quantities and shelf life. Additionally, businesses have to balance the benefits of stockpiling with risks such as spoilage, contamination or regulatory fines.

Ready to Cut Losses From Fuel Discrepancies?

From theft prevention to reconciliation, smart systems ensure your delivered fuel matches what’s received, so no more costly surprises.

Optimizing Fuel Inventory Management For Retailers

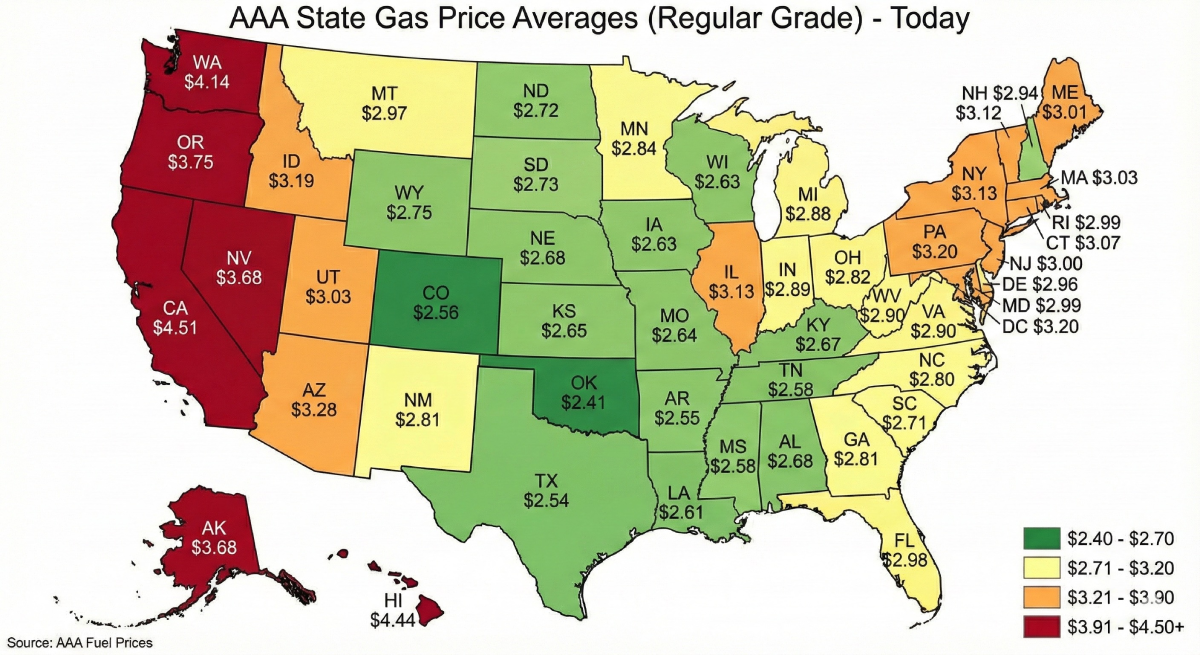

In fuel inventory management, retailers face challenges such as fluctuating customer demand and competitive pricing. Their solutions are;

- Dynamic pricing tools to adjust based on demand

- Forecasting software to anticipate peak periods

- Real time monitoring to prevent shortages.

Fuel inventory systems help suppliers improve customer relations and reduce cost.

Advanced Tank Monitoring For Maximum Accuracy And Efficiency

Advanced monitoring systems employ ultrasonic sensors, IoT devices, and cloud dashboards to deliver precise, real-time readings.

These fuel inventory monitoring tools reduce manual errors, save staff time, and optimize maintenance schedules. Automated alerts prevent stockouts and overfills.

For organizations managing multiple sites, advanced monitoring centralizes data, offering managers a clear view across locations. This enhances both efficiency and compliance.

The Role Of Data Analytics In Fuel Inventory Management

Data analytics turns raw data into actionable insights. Consumption patterns reveal inefficiencies and predictive analytics help forecast demand and optimize procurement. Businesses can also catch abnormalities such as leakages or theft using analytics.

Data driven strategies combined with fuel inventory software help businesses make better decisions and strengthen profitability.

Benefits Of Just-In-Time Inventory For Fuel Businesses

Just-in-time inventory is a strategy used in business management that involves producing or receiving goods only when needed. This approach reduces the need for storage as the stock levels are kept low.

When JIT is paired with fuel inventory management systems, it leads to a drop in overhead cost and aligns supply and demand.

JIT usage can lead to supply chain disruptions, so to limit this, you can use forecasting tools, forming good relations with suppliers and tracking real time data using fuel inventory monitoring systems.

How Forecasting Helps Prevent Fuel Shortages

Forecasting models use historical data, seasonal trends and external factors such as regulations and weather patterns to estimate future behavior or happenings. Integrating forecasting tools with fuel inventory management software helps businesses prevent shortages by warning about possible upcoming supply chain disruptions, thereby assuring continuous operations.

If your business’ efficiency relies on stable fuel inventory management, integrating forecasting software into your operations will help your organization to maximize profits, reduce losses and protect customer trust.

The Hidden Costs Of Poor Fuel Inventory Management

Neglecting proper fuel inventory management will hurt the business and cause it to endure hidden costs such as financial losses from leakages or theft, operational failures from faulty tracking, declining trust from customers due to shortages and even possible legal harm due to compliance violations.

These issues in the long term demonstrate the importance of fuel inventory tracking solutions in ensuring sustainable operations and profitability.

How To Use Turnover Ratios For Better Fuel Inventory Management

Turnover rations measures how quickly fuel stock is consumed and how quickly it is replenished.

| Turnover level | Meaning | Recommended action |

|---|---|---|

| Low Turnover | This means fuel moves too slowly risking spoilage of unused stock and capital lockup | If this happens, you should reduce your purchasing volume and track consumption patterns with proper fuel inventory monitoring |

| Moderate turnover | This indicates a balance between demand and storage capacity. | Keep your current procurement strategy, monitor seasonal trends and use fuel inventory management systems to ensure stability |

| High turnover | High turnover means you’re selling more than you store. With this, you can have issues with shortages and unmet demand. |

How To Conduct Effective Fuel Inventory Audits (H2)

Audits verify the accuracy of records and identify inefficiencies. Effective audits involve:

- Regular checks of tank levels.

- Comparing data with fuel inventory management systems.

- Using digital tools for automated reporting.

Audits enhance accountability and compliance, making them vital for regulated industries.

How To Build Strong Supplier Relationships For Fuel Inventory Management (H2)

Suppliers play a central role in reliable fuel operations. Building strong relationships involves:

- Transparent communication.

- Fair contract negotiations.

- Shared use of fuel inventory systems for coordination.

Collaboration reduces risks of delays, ensures consistent supply, and improves pricing leverage.