Key Takeaways

- A diesel engine’s operation is distinct from gasoline engines, relying on hot compressed air and precise fuel injection rather than sparks.

- The combustion process initiates with the injection of atomized fuel into this hot air.

- Like other internal combustion engines, diesels use a starter motor to crank the engine and begin the compression cycle.

- For cold starts, particularly in winter, glow plugs are employed to assist the engine in firing up.

- Diesel engines are known for their robust operation and high torque, which can be attributed to their higher compression ratios and the energy density of diesel fuel.

Table of Contents

How Do Diesel Engines Work?

Diesel engines operate on the principle of compression ignition. Air is drawn into each cylinder and compressed by the piston, causing it to heat up significantly. Fuel is then injected, mixes with the hot air, and ignites, driving the piston. This compression-induced heat, rather than a spark, is responsible for ignition.

This reliable power cycle is fundamental to trucks, marine vessels, heavy equipment, and generators. When considering how diesel engines function, the process follows a sequence of air intake, then fuel injection, followed by expansion. Their applications are diverse, ranging from pickup trucks to large industrial plants.

What Is A Diesel Engine?

A diesel engine is an internal combustion machine that turns the chemical energy of fuel into mechanical work through compression ignition. It compresses air, injects fuel, and uses the expanding gases to move pistons and the crankshaft. This explains what the diesel engine do in cars, trucks, and generators. The diesel engine explained in one line is, it burns fuel without a spark.

How Does A Diesel Engine Turn Fuel Into Power?

Fuel is pressurized and timed to inject into hot compressed air. Atomized droplets vaporize, mix, and reach auto ignition, releasing heat. That pressure pushes the piston down, rotates the crankshaft, and delivers torque to the wheels or shaft. If you wondered what makes a diesel engine fire, it is heat and pressure, not a plug.

What Are The Basic Principles Of A Diesel Engine?

Diesel engine operation is defined by two key principles. Firstly, the engine compresses only air, generating temperatures high enough to ignite injected fuel. Secondly, it operates with higher compression ratios and cylinder pressures compared to gasoline engines, which enhances thermodynamic efficiency. These principles explain how does diesel work in a practical sense.

Those who inquire how do diesels work or diesel engine works are often drawing comparisons to gasoline engines. It’s important to remember that the distinction lies in compression ignition and precise fuel delivery at the end of compression, rather than a premixed spark event.

Curious How Diesel Engines Generate So Much Power?

Diesel engines produce immense torque thanks to high compression ratios, long strokes, and precision fuel injection. Learn how these mechanics work together to deliver the strength behind trucks, ships, and heavy equipment.

How Does Diesel Combustion Work?

Diesel combustion begins with the injection of a fine mist into hot air. The droplets vaporize and mix with oxygen, igniting in stages influenced by pressure, temperature, and turbulence, resulting in a controlled, rapid burn.

Effective atomization and in-cylinder air motion are crucial. The design of the piston bowl and port encourages swirl and squish, which accelerates mixing and enhances the completeness of the burn. This process optimizes diesel engine ignition for both power output and reduced soot emissions.

What Ignites The Fuel In A Diesel Engine?

If you ask what ignites the fuel in a diesel engine, the answer is hot compressed air. There are no spark plugs, so combustion begins when diesel meets air above its auto-ignition temperature. In cold weather, glow plugs preheat the chamber to help the first firing cycles.

Diesel engines ignite fuel using the heat generated from compression, eliminating the need for spark plugs. Glow plugs are utilized to aid in cold starts, but they disengage once the engine is running.

Wondering Why Diesel Engines Don’t Need Spark Plugs?

It’s all about heat and pressure—diesel fuel ignites when injected into superheated air, not by sparks. Discover how compression ignition makes diesel engines both durable and efficient.

How Does A Diesel Engine Start?

Curious about how a diesel engine starts or do diesels have starters? What you need to know is, a battery powers a starter motor that cranks the engine to a minimum speed. Air is drawn in, compressed, and fuel is injected. If it is cold, glow plugs preheat before and briefly after starting to stabilize combustion.

From cars to starting diesel trucks, the sequence is the same. Crank with the starter, inject fuel, ignite by compression, then the engine runs on its own. That is the essence of starting a diesel engine or how to start a diesel engine.

What Are The Key Differences Between Diesel And Gasoline Engines?

Diesel and gasoline engines both power vehicles, but their fundamental operating principles and resulting characteristics differ significantly, influencing performance, fuel efficiency, and maintenance requirements.

| Feature | Diesel Engine | Gasoline Engine |

|---|---|---|

| Ignition Method | Compression ignition | Spark ignition |

| Compression Ratio | Typically higher | Lower |

| Fuel Energy | More energy per gallon (aids real-world economy) | Less energy per gallon |

| Construction | Built stronger for higher pressure | Lighter construction |

| Air Supply | Often uses turbocharging | Uses a throttle for air intake |

| Maintenance Focus | Prioritizes injector cleanliness and filtration | Spark plug and ignition system maintenance |

What Are The Four Strokes Of A Diesel Engine Cycle?

Diesel engines operate through a four-stroke cycle:

- Intake: Air is drawn into the engine.

- Compression: The air is compressed, causing its temperature to rise significantly.

- Power: Fuel is injected into the hot, compressed air, igniting and expanding rapidly, which drives the engine’s piston.

- Exhaust: Spent gases are expelled from the engine.

How Does The Thermodynamic Cycle In A Diesel Engine Work?

The core principle behind diesel engine operation is the Diesel cycle, which contrasts with the Otto cycle used in gasoline engines. In a diesel engine, heat is added closer to constant pressure, while compression and expansion phases are largely isentropic. This design allows for higher compression ratios without the risk of engine knock, a key factor in improving efficiency and generating real-world torque. The mechanics of how a diesel engine works, step by step, are explained through this cycle, detailing the energy conversion process that drives the pistons.

| Feature | Diesel Cycle |

|---|---|

| Heat Addition | Occurs closer to constant pressure. |

| Compression | Mostly isentropic, supports higher ratios. |

| Expansion | Mostly isentropic. |

| Efficiency | Improved due to higher compression. |

| Torque Generation | Directly related to combustion theory. |

| Engine Type | Diesel engines. |

Want To Understand Modern Diesel Efficiency?

Today’s diesels use common rail injection, turbochargers, and precision controls to deliver higher mileage and lower emissions. See how engineering advances keep diesel engines relevant in the 21st century.

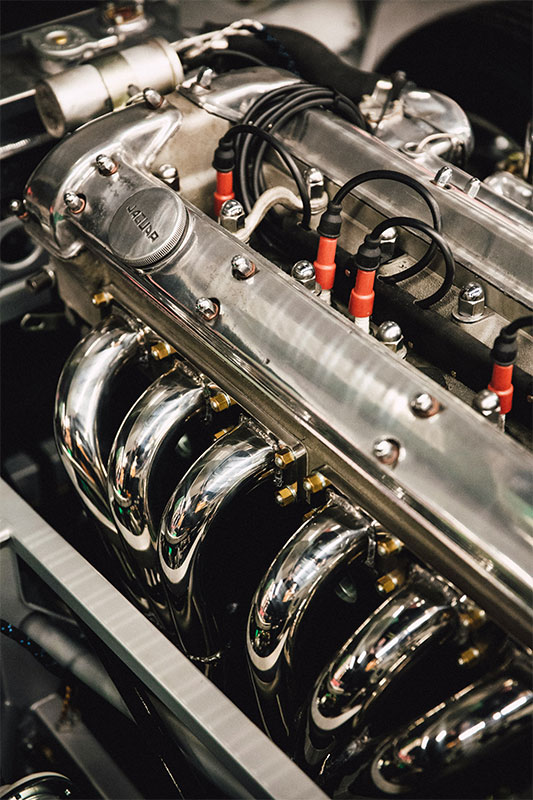

What Components Make Up A Diesel Engine?

These parts work in concert with precise timing to achieve the compression-ignition necessary for diesel engine operation. Whether searching for “diesel fuel engine” or “diesel motor works,” these integrated components are responsible for converting fuel into mechanical motion. The engine’s design is specifically engineered to withstand the extreme high pressures and temperatures inherent in the compression ignition process.

How Does A Diesel Fuel Injection System Work?

Modern diesel engines achieve smooth and efficient combustion under varying loads through sophisticated fuel injection systems. Common rail and unit injector systems precisely pressurize fuel, delivering atomized sprays into the combustion chamber at the exact optimal moment. This meticulous control, often involving multiple small injections per combustion cycle, significantly reduces combustion noise and mitigates harmful emissions by carefully managing the rate of pressure rise within the cylinder.

To fully grasp the intricacies of diesel engine combustion and the process by which diesel engines ignite fuel, it is crucial to consider three primary, computer-controlled factors:

- Injector pressure, which dictates the force of the fuel spray

- Spray pattern, which determines how the fuel mixes with air

- Injection timing, which precisely controls when the fuel is introduced into the cylinder relative to the piston’s position.

These interconnected elements are all meticulously regulated by the engine’s electronic control unit (ECU) to optimize performance, fuel economy, and emissions.

What Are The Main Types Of Diesel Injection Systems?

Common rail systems store fuel at exceptionally high pressure, enabling precise and flexible multi-injection events for optimized combustion. Older mechanical designs include inline and rotary distributor pumps. Unit injectors, on the other hand, integrate both the pump and the injector directly at each cylinder. Each of these fuel injection architectures represents a distinct balance of cost, control capabilities, and long-term durability.

If you are learning about a diesel engine explained or diesel engine animation, these architectural advancements highlight how engineers have continuously improved fuel control to refine diesel combustion processes and enhance overall engine efficiency.

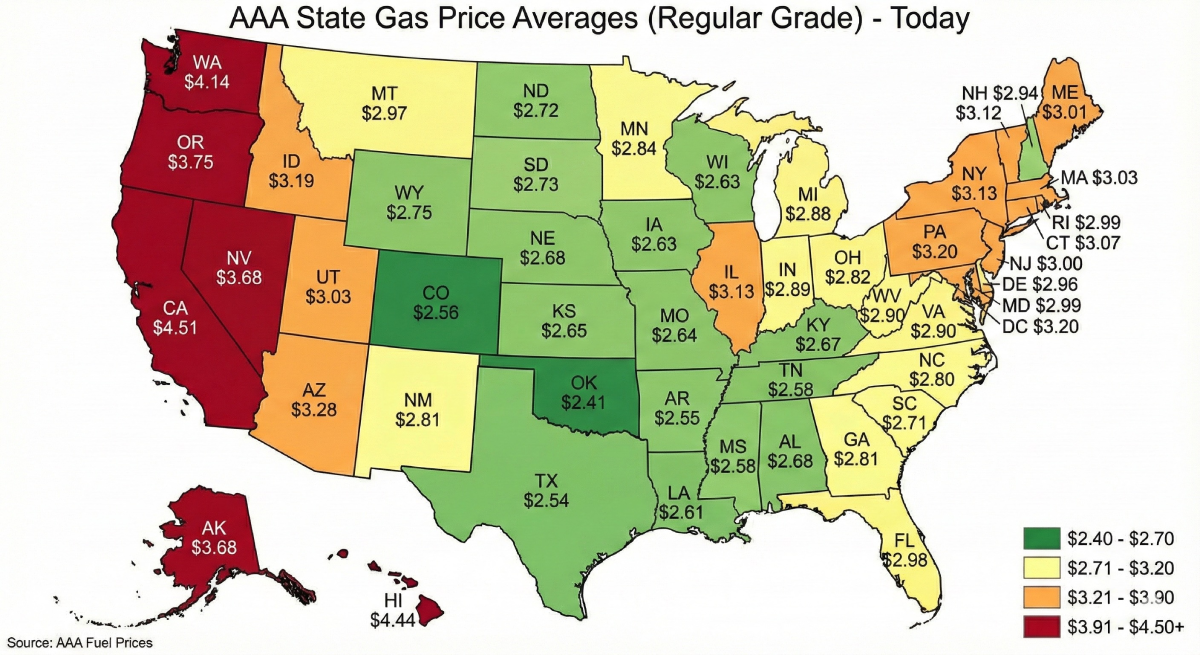

What Makes Diesel Fuel Different From Gasoline?

Diesel is denser and contains more energy per gallon, which helps fuel economy. It also resists auto ignition less than gasoline in hot compressed air, which suits compression ignition. These fuel traits support the unique diesel engine working principle and load carrying strength.

If you are asking how diesel looks, you should note it is usually clear to pale yellow and slightly oily to the touch. Its higher energy content explains economic gains.

How Is Diesel Engine Torque Generated So Effectively?

Diesel engines achieve their remarkable power and efficiency through a combination of high compression ratios, extended piston strokes, the use of turbochargers, and precise fuel injection. This intricate design generates significant pressure within the cylinders during the power stroke. A longer stroke length provides increased leverage on the crankshaft, translating more of that cylinder pressure into rotational force. Furthermore, the use of energy-dense diesel fuel contributes to a greater amount of work produced per combustion cycle. The cumulative result of these engineering principles is the characteristic confident towing and hauling capabilities for which diesel engines are renowned.

Therefore, when comparing the operational principles of a diesel engine to that of a gasoline engine, it is crucial to remember that the substantial torque generated by a diesel engine originates from the immense cylinder pressure acting over a considerable distance during the power stroke. This fundamental difference elucidates why a diesel engine produces such strong combustion and high power output even at low revolutions per minute (rpm).

What Makes Diesel Engines More Efficient Than Gasoline Engines?

Diesel engines achieve higher thermodynamic efficiency due to several key factors: less throttling loss, higher compression ratios, and leaner operation. These characteristics enable diesel engines to extract more useful work from each unit of fuel energy compared to gasoline engines. This inherent efficiency is also maintained more consistently under varying loads, making them particularly well-suited for applications where power and fuel economy are critical. Consequently, diesel engines are the preferred choice for fleets and heavy-duty users, including commercial trucks, buses, construction equipment, and agricultural machinery, where their durability, power, and fuel efficiency translate into significant operational advantages.

Why Do Diesel Pistons Have A Bowl Design?

The meticulously designed bowl shape within the piston plays a crucial role in directing the air’s motion, fostering both swirl and squish. This controlled movement significantly accelerates the mixing process as fuel is injected. Enhanced mixing is paramount for achieving cleaner and more complete diesel combustion, ultimately leading to higher efficiency in the engine’s operation. Indeed, the precise geometry of this bowl is a major lever in modern engine design, allowing engineers to fine-tune the combustion process.

Therefore, if you’ve ever pondered what mechanism does a diesel engine use to achieve combustion in the combustion chamber, the answer intricately involves the piston bowl’s shape. This critical design element guides the intricate pattern of fuel jets and the subsequent flame propagation, ensuring a stable and efficient burn that powers the vehicle.