Key Takeaways

- Average skid steer fuel consumption per hour ranges from 1.5–3.5 gallons.

- Skid steer fuel tank size varies 15–30 gallons depending on model.

- High-hour machines reduce efficiency, increasing skid steer fuel consumption per hour costs.

- Attachments and terrain strongly influence Bobcat fuel consumption per hour significantly.

- Use cost calculators to estimate skid steer operating cost per hour accurately.

Table of Contents

Skid Steer Fuel Consumption Per Hour

The average skid steer fuel consumption per hour typically ranges from 1.5 to 3.5 gallons per hour, depending on the model. Smaller units with 40–50 horsepower often use closer to the lower end, while larger, high-horsepower machines can exceed 3 gallons per hour. Understanding this range helps you estimate costs before starting a project.

Several factors influence how much fuel a skid steer uses per hour. Engine size is a primary driver, but the type of work matters as well. Heavy digging, lifting, or constant travel will burn more fuel than light grading. Operator habits also play a major role, for example excessive idling or abrupt operation increases fuel usage unnecessarily.

To manage skid steer fuel consumption, you should measure and track actual usage with onboard telematics or manual logbooks. Monitoring daily burn rates gives you clear insights into efficiency, helping reduce waste and plan accurate operating costs.

How Much Fuel Does A Skid Steer Use Per Hour?

Fuel consumption varies between manufacturer specifications and real-world job site reports, as shown below:

| Skid steer type | Manufacturer specs | Reported real world users | Notes |

|---|---|---|---|

| Small (40-50 HP) | 1.5-2 | 1.8-2.2 | Light landscaping and grading |

| Mid-size (60-70 HP) | 2-2.8 | 2.5-3 | Mixed construction tasks |

| Large (75+ HP) | 3-3.5 | 3.5-4+ | Heavy excavation and lifting |

The differences between light-duty and heavy-duty operations are;

- Light-duty jobs (grading, snow clearing) typically consume 20–30% less fuel.

- Heavy-duty operations push engines harder, raising burn rates above manufacturer averages.

- Continuous idling can increase daily fuel totals significantly.

How Much Fuel Does A Bobcat Use Per Hour?

When it comes to Bobcat fuel consumption per hour, most models typically use between 1.8 and 3.4 gallons per hour, depending on size and workload. Bobcat machines are known for efficient engines that balance power with fuel economy, making them reliable for contractors managing fuel budgets.

A key reason Bobcat fuel consumption per hour stays competitive is the brand’s Smart Cooling and load-sensing hydraulics, which adjust performance to match demand. These design features reduce unnecessary fuel burn compared to older or less efficient skid steers, ensuring operators get maximum productivity without overspending on fuel.

Skid Steer Fuel Tank Size

The average skid steer fuel tank size ranges from 15 to 30 gallons, depending on machine class. Compact skid steers generally hold around 15–20 gallons, while mid-size models offer 20–25 gallons. Larger, heavy-duty machines can carry up to 30 gallons or more.

Tank capacity directly impacts how many gallons a skid steer holds and how often you need to refuel. Smaller tanks may require refilling during long shifts, while larger tanks allow operators to work extended hours without interruption. This difference can affect project timelines and labor efficiency.

For demanding job sites, larger skid steer fuel tank size brings real advantages. Operators spend less time pausing to refuel and more time completing tasks. This efficiency is particularly valuable in construction, agriculture, and landscaping where downtime translates to higher costs.

Worried About Skid Steer Fuel Costs?

Fuel costs can add up fast on busy job sites—but you don’t have to overspend. With accurate burn rate data and smart practices, you can plan budgets better and cut waste. Learn proven strategies to stretch every gallon and maximize operating hours.

How Much Fuel Does A Bobcat T770 Use Per Hour?

The Bobcat T770 fuel consumption per hour typically ranges between 2.7 and 3.5 gallons, depending on workload intensity. Light grading or landscaping tasks keep usage at the lower end, while heavy lifting or excavation drives it higher. Real-world reports confirm that operator habits and extended idling also significantly impact overall burn rates.

How Much Fuel Does A Bobcat E35 Use Per Hour?

The Bobcat E35 fuel consumption per hour averages 1.5 to 2.0 gallons, according to both manufacturer specs and operator feedback. Contractors note its efficiency during trenching and light excavation, especially when compared with larger excavators. Real-world users emphasize that smooth operation and limited idling further improve fuel economy, making the E35 a cost-effective choice for smaller projects.

How Much Fuel Does An Excavator Use Per Hour?

The average excavator fuel consumption per hour typically ranges from 3 to 6 gallons, depending on size and workload. When compared to skid steer fuel consumption per hour, excavators of similar horsepower generally burn more fuel due to larger hydraulic systems and constant heavy lifting. For example, a 70-horsepower skid steer may average 2.5 gallons per hour, while a comparable compact excavator consumes closer to 3.5 gallons. This difference highlights how machine design and hydraulic demands influence overall efficiency.

Excavators can sometimes prove more efficient than skid steers when assigned to specialized tasks. For trenching or deep digging, how much fuel an excavator uses per hour may balance out because it completes jobs faster, reducing total run time. Conversely, for light-duty operations like grading or material transport, a skid steer fuel consumption rate is usually lower, making it more cost-effective. Matching the right machine to the task is essential for fuel savings.

How Much Fuel Does A CAT 299D3 Use Per Hour?

The CAT 299D3 fuel consumption per hour is estimated at 3.0 to 3.5 gallons, according to Caterpillar’s manufacturer data. This range reflects average use under standard operating conditions, such as moderate grading or lifting tasks. The machine’s 98-horsepower engine and advanced hydraulics contribute to steady, predictable fuel burn rates.

Field reports from operators indicate slightly higher figures during heavy-duty applications. When performing continuous excavation or demanding material handling, usage can rise to 3.8 gallons per hour. Proper maintenance, reduced idling, and efficient operator habits help keep the CAT 299D3 fuel consumption per hour closer to factory benchmarks.

What Is A Lot Of Hours On A Skid Steer?

A typical skid steer lifespan ranges between 5,000 and 7,000 hours under normal use, though heavy-duty models may exceed 8,000 hours with proper care. Generally, crossing the 5,000-hour mark is considered “a lot of hours on a skid steer.” Usage intensity, maintenance history, and operator habits all determine how long a machine remains productive.

High-hour machines often show reduced efficiency, including increased skid steer fuel consumption per hour. Worn engines, hydraulic components, and fuel systems struggle to maintain peak performance, which can raise fuel burn rates. As machines age, idling waste and breakdown frequency also increase, translating into higher operating costs and lower reliability compared to newer equipment.

By brand, Caterpillar and Bobcat skid steers average 5,000 to 6,500 hours, while some John Deere and Case models have been reported to last beyond 7,000 hours with consistent servicing. Light-duty use typically extends life expectancy, whereas constant excavation or lifting can shorten total operational lifespan.

Want Accurate Skid Steer Hourly Cost Estimates?

Guesswork leads to surprise expenses. By combining fuel, maintenance, and depreciation data, you can calculate your true hourly costs before a project begins. Use reliable calculators and real-world burn rates to keep your bids competitive and your margins healthy.

How Fast Does A Skid Steer Go?

The average skid steer travel speed ranges between 7 and 10 miles per hour, depending on model and size. Compact units typically reach speeds around 7 mph, while larger models with two-speed transmissions can achieve 12 mph or more. For example, a Bobcat S770 can travel up to 12.3 mph, making it one of the faster machines in its class. These speeds are sufficient for most construction, landscaping, and agricultural tasks that require frequent repositioning across job sites.

Speed directly impacts skid steer fuel consumption per hour. Operating at higher speeds or in aggressive drive modes typically burns more fuel due to increased engine load and hydraulic demand. Conversely, working at moderate speeds helps conserve fuel, especially during tasks like grading or loading. Understanding how speed settings influence both productivity and efficiency allows you to balance project timelines with fuel economy for cost-effective operation.

Skid Steer Operating Cost Per Hour

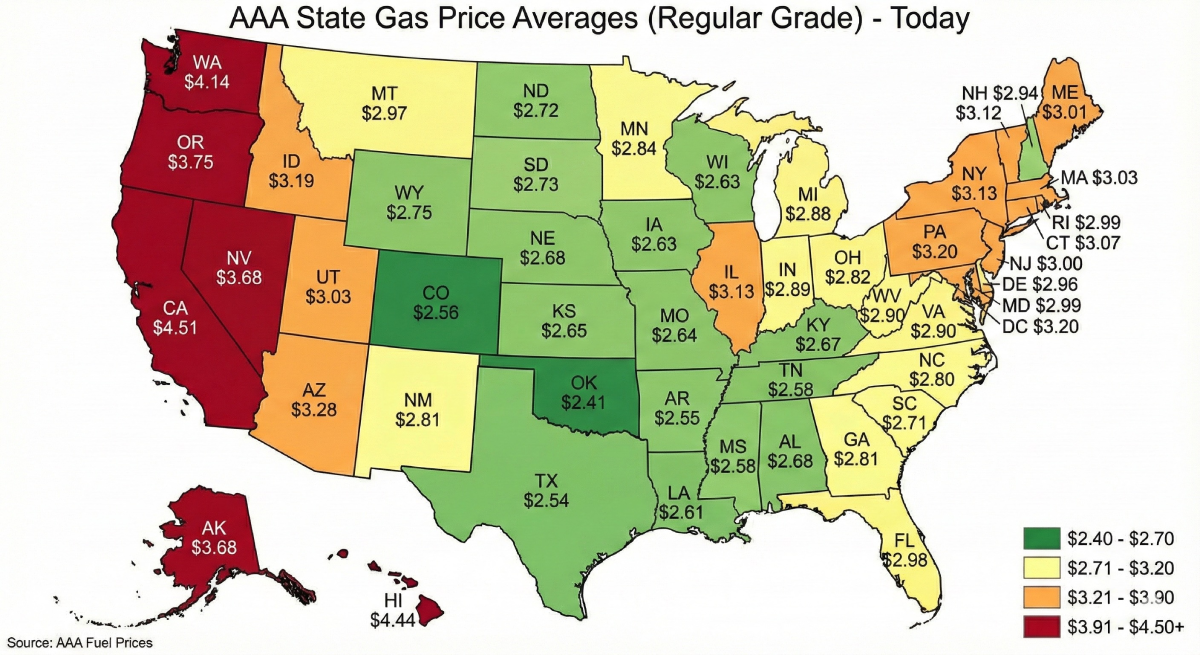

The average skid steer operating cost per hour is made up of three major elements: fuel, maintenance, and depreciation. Fuel alone can represent $5–$10 per hour depending on skid steer fuel consumption per hour and local diesel prices. Maintenance, including oil changes, filters, tires, and hydraulic repairs, adds another $3–$6 per hour. Depreciation is also significant, especially within the first 3,000 hours of use, averaging $7–$10 per hour.

Because these costs vary widely by brand, workload, and hours of operation, using a reliable tool is essential. A heavy equipment cost calculator helps you estimate total ownership expenses accurately. This makes it easier to compare options and avoid surprises. Before you buy, analyzing full hourly costs ensures your skid steer investment remains productive and financially sustainable across its operating life.

Ready to Lower Your Skid Steer Operating Expenses?

From reducing idling time to matching machine size with workload, small changes make a big difference in fuel efficiency. Learn expert techniques contractors use every day to extend machine lifespan and cut per-hour operating costs.

Minimizing Fuel Costs For Compact Loaders And Skid Steers

Lowering operating expenses requires smart practices to optimize daily fuel usage:

- Reduce idling time to cut skid steer fuel consumption per hour.

- Use the maintenance schedules recommended by the manufacturer for peak fuel efficiency.

- Select the right skid steer fuel tank size for fewer refueling interruptions.

- Train operators on smooth handling to avoid unnecessary fuel burn.

- Match machine size to workload as oversized loaders will waste fuel.

- Track actual usage with telematics to monitor costs accurately.

- Compare models’ efficiency, including Bobcat fuel consumption per hour before purchase.

- Plan work schedules to maximize continuous operation and minimize downtime.

Do Attachments Affect Skid Steer Fuel Consumption?

Yes, attachments significantly impact skid steer fuel consumption per hour by increasing engine load. High-demand tools like trenchers, augers, or cold planers require more hydraulic power, raising fuel burn rates compared to simple buckets or forks. Weather and terrain also play a role—muddy, uneven ground forces the engine to work harder, further increasing consumption.

To minimize costs, select attachments designed for efficiency and match them to the task. Misconceptions exist that all attachments drastically reduce economy, but industry standards show well-maintained tools actually preserve performance. Refer to manufacturer charts for specific machines to ensure balanced operation and improved fuel efficiency.

Skid Steer Fuel Mileage

Although skid steers aren’t rated in miles per gallon, you can estimate skid steer fuel mileage by dividing distance traveled by fuel consumed. For example, if a machine burns 2 gallons per hour and covers 8 miles in that time, efficiency equals 4 mpg. This calculation helps compare skid steer fuel consumption per hour with other machines and plan job-site travel more effectively.

How Much Fuel Does Compact Construction Equipment Use?

Compact equipment, including skid steers, mini excavators, and compact track loaders, averages 1.5 to 4 gallons per hour depending on engine size and workload. For instance, skid steer fuel consumption per hour typically falls between 1.5–3.5 gallons, while mini excavators like the Bobcat E35 average closer to 2 gallons. These figures highlight how machine type and application strongly affect operating expenses.

Since how much fuel compact construction equipment uses per hour can vary widely in real-world conditions, it’s best to compare directly. Contacting local dealers for demo trials allows you to test efficiency firsthand before making a purchase. This ensures the right equipment balances productivity with cost savings.