Key Takeaways

- Confirm Texas above-ground storage tank regulations applicability before installation, operation, alteration, closure.

- Register per Texas above ground storage tank regulations and keep current inspection records.

- Provide secondary containment sized to 110% capacity, inspect dikes, liners, drains regularly.

- Implement OSHA training, and confined-space permits for operations and maintenance.

- Align NFPA design distances, bonding, grounding, with SPCC plans and procedures sitewide.

Table of Contents

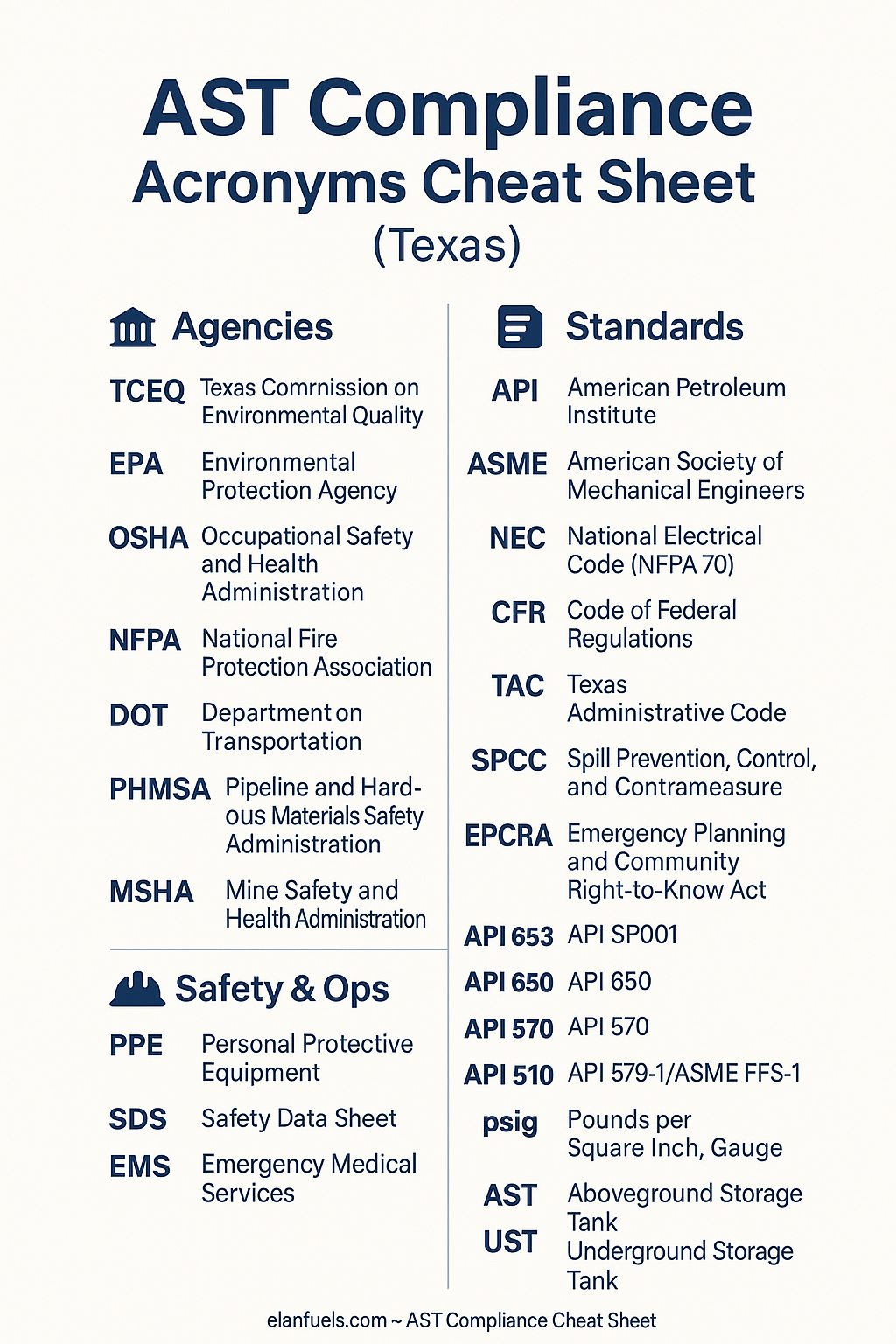

Texas Above-Ground Storage Tank Regulations

Under Texas above ground storage tank regulations, the Texas Commission on Environmental Quality (TCEQ) serves as the lead state agency for AST siting, installation, operations and closure. TCEQ issues rules, registrations and guidance. TCEQ also coordinates with fire officials and relevant federal programs. Oversight focuses on preventing releases, safeguarding groundwater and assuring emergency access. For operators, Texas above ground storage tank regulations convert into practical duties, maintaining accurate inventory, keeping records, reporting suspected releases promptly and demonstrating compliance during periodic inspections and enforcement follow-ups.

TCEQ rules trigger based on storage capacity and product classes. Most petroleum ASTs over specified gallon thresholds require registration, visible tank labeling and adherence to construct standards addressing foundations, corrosion protection, venting , gauging overfill alarms and secondary containment. Facilities must keep spill kits, inspect tanks and piping routinely, test leak detection equipment and maintain written records available to inspectors. Where multiple tanks are present, aggregate capacity can determine applicability, and temporary tanks used at job sites may have distinct notification and siting conditions that still require protective controls.

While petroleum fuels are usual focus, TCEQ standards also cover hazardous substances in ASTs with federal obligations under SPCC, EPCRA and fire codes. Determining applicability depends on product, capacity, location, access to water, schools or public ways. If your facility needs help closing gaps and documenting conformity with Texas aboveground storage tank regulations and Texas above ground storage tank regulations, consult qualified compliance experts. The right audit, design review and training plan can prevent serious fines and operational delays.

Petroleum Storage Tanks Registrations: Am I Regulated?

Whether a petroleum AST must be registered with TCEQ depends on product, capacity and use. Texas aboveground storage tank regulations apply when petroleum is stored for business purposes above set thresholds. Aggregated volumes, spill risk, and distribution connections can also trigger registration, recordkeeping and inspection responsibilities.

Regulated tanks complete registration, labeling, design and periodic inspection requirements. Exempt tanks fit narrowly defined categories, often smaller, temporary or noncommercial. Accurate filings keep permits current and prove diligence during audits. Stay aligned with Texas aboveground storage tank regulations to prevent penalties, delays or shutdowns caused by lack of paperwork and applicability.

Unsure If Your Texas AST Needs TCEQ Registration?

Many petroleum ASTs must register under 30 TAC 334 Subchapter F, often triggered by capacity and aggregation. We’ll assess applicability, handle filings, and prep your records so you’re audit-ready.

What Is The Texas Administrative Code For Aboveground Storage Tanks?

In the Texas Administrative Code, aboveground storage tanks (ASTs) are governed in 30 TAC Chapter 334, Subchapter F. These rules set purpose and applicability (§334.121), definitions (§334.122), installation notification (§334.126), registration (§334.127), a fee of $25 (§334.128), release reporting and corrective action (§334.129), and reporting and recordkeeping (§334.130), along with other general provisions (§334.132). Coverage includes tank siting near property lines, integrity, spill control, and administrative processes. Enforcement and variances are addressed. Together they translate statute clearly into operational requirements for siting, design, inspection, and documentation.

Section 334.127 requires ASTs existing on or after September 1, 1989 to be registered on agency forms, and new or replacement tanks registered within 30 days after first petroleum fill; exemptions apply. Section 334.2 defines “petroleum storage tank,” encompassing ASTs and underground storage (USTs) regulated by the commission key for determining applicability and whether a vessel falls under Subchapter F obligations.

These TAC rules operate under the Texas Water Code. Section 26.3441 specifies non-exempt ASTs are subject to registration under §26.346 and to TCEQ regulation only as prescribed by Subchapter I, anchoring scope and preemption. Practically, align programs with texas above-ground storage tank regulations and texas above ground storage tank regulations to ensure statutory and rule-level conformity.

What Are The OSHA Regulations For Above Ground Storage Tanks?

- OSHA(Occupational Safety and Health Administration) establishes baseline workplace safety standards for AST facilities, complementing environmental compliance programs in Texas.

- Key references include 29 CFR 1910.106 for flammable liquids handling, storage, and tank appurtenances requirements.

- Employers must assess hazards, provide PPE, and train workers on fueling, transfer, and emergency procedures.

- Installation requires safe clearances, stable foundations, ventilation, electrical classification, and bonding or grounding controls verified.

- Handling mandates approved containers, compatible hoses, shutoff valves, flame arrestors, and strict no-smoking enforcement policies.

- Inspection programs cover tanks, piping, spill kits, overfill alarms, gauges, ladders, and access paths integrity.

- Written procedures must address hot work, lockout/tagout, confined spaces, housekeeping, and fire extinguishers selection readiness.

- Emergency action plans require alarms, evacuation routes, spill response coordination, and post-incident reporting reviews documentation.

- These obligations apply regardless of Texas aboveground storage tank regulations administered by environmental authorities statewide.

- Align with texas above ground storage tank regulations and OSHA controls to prevent injuries effectively.

What Are The Containment Requirements For Above Ground Storage Tanks?

Secondary containment is a protective barrier, such as a dike, berm, curbing, or double-walled designed to capture releases before they reach soil or water. Under Texas aboveground storage tank regulations, containment prevents drips, spills, and failures from becoming environmental incidents, simplifying cleanup. Effective systems are liquid-tight, compatible with the stored product, properly sized, and maintained. Routine inspections verify wall integrity, drain valves, and sump capacity so containment performs when tanks, piping, or fittings leak.

The “110 percent” rule which is a rule of thumb in some local fire codes requires containment to hold at least 110% of the largest tank or compartment. Smaller day tanks and totes may use spill pallets or double-walled designs. Larger ASTs typically need engineered dikes. Multi-tank facilities size to the largest vessel while managing volumes and precipitation. As capacity increases, documentation, inspection, and maintenance expectations rise under Texas above ground storage tank regulations. Verify sizing, materials, drainage, and valve controls match your products, transfer rates, and site layout.

What Is The NFPA Code For Above Ground Fuel Storage Tanks?

NFPA ( standards set fire protection baselines for aboveground fuel tanks, complementing compliance under texas above-ground storage tank regulations and texas above ground storage tank regulations. NFPA 30 governs tanks, containers, piping, venting, and emergency relief; NFPA 30A adds rules for dispensing facilities. NFPA 1 references these provisions, while NFPA 37 and NFPA 70 address engine installations and electrical classification. Together, these codes influence construction, clearances, separation distances, overfill prevention, vehicle impact protection, and fire suppression. Because authorities may amend requirements and insurers add conditions, consult certified fire protection engineers to validate design, placement, and documentation significantly reducing delays and insurance risk.

- NFPA 30: tanks, containers, piping, venting, emergency relief, and spill control.

- NFPA 30A: fuel dispensing facilities, canopies, crash protection, electrical, and signage.

- NFPA 1: adopts references; governs fire access, hydrants, and emergency planning.

- NFPA 37: engine-associated tanks; separation distances, fuel lines, and enclosures.

- NFPA 70 (NEC): area classification, bonding, grounding, and wiring methods.

- Design impacts: materials, foundations, fire barriers, overfill alarms, foam or water protection.

- Placement impacts: property lines, public ways, buildings, ignition sources, and vehicles.

- Operations: inspections, hot work controls, emergency shutdowns, training, drills, and documentation.

- Coordinate NFPA provisions with local amendments, insurer requirements, and TCEQ registration conditions carefully.

- Describe NFPA standards relevant to ASTs, including NFPA 30 and others.

- Explain how these fire protection codes impact design and placement.

- Selling point: Suggest consulting certified fire safety engineers to ensure installations meet NFPA requirements and lower insurance risks.

Is Your Secondary Containment Truly 110%?

Texas rules expect liquid-tight, compatible containment sized to at least 110% of your largest tank, with managed precipitation and valve control. We’ll verify sizing and document fixes to pass inspections.

Are Aboveground Storage Tanks Regulated By The EPA?

- EPA regulates oil AST facilities via SPCC (40 CFR 112) to prevent water discharges.

- SPCC mandates plans, containment, inspections, records aligned with texas above-ground storage tank regulations.

- Aggregate aboveground oil capacity drives applicability; qualified facilities may self-certify SPCC plans.

- Facilities posing substantial harm may require Facility Response Plans addressing worst-case discharges.

- EPA oversight complements OSHA safety and NFPA fire codes during handling, transfer, and maintenance.

- Compliance integrates Texas above ground storage tank regulations with spill prevention, reporting, and corrective measures.

EPA rules mainly target oil under SPCC, ASTs often fall under Texas above-ground storage tank regulations administered by TCEQ. Exemptions include small containers below thresholds, motive-power fuel tanks, permanently closed tanks, and agricultural uses. Overlap occurs where SPCC planning, inspections, and spill reporting intersect with state registration, construction, and containment standards. Coordinate texas above ground storage tank regulations with federal obligations to avoid gaps, records, or duplicate procedures complicating audits.

What Is The Critical Zone Of A Storage Tank?

The critical zone of a storage tank is the highest-risk interface where product, air, and structural elements meet, typically shell-to-bottom welds, floor plates, nozzles, manways, and roof-to-shell joints. In practice under texas above-ground storage tank regulations and texas above ground storage tank regulations, this zone concentrates corrosion, settlement stresses, and leak pathways. Effective maintenance focuses on corrosion allowances, coatings, cathodic protection, gasket integrity, and gauging. Operators prioritize tightness testing, ultrasonic thickness readings, and annular inspections, while housekeeping prevents water accumulation and corrosion. By targeting the critical zone in inspection plans, facilities reduce release risk, extend service life, and improve audit readiness.

Close Your SPCC, OSHA & NFPA gaps fast

Align SPCC (40 CFR 112), OSHA 1910.106/1910.146, NFPA 30/30A, and API 653/STI SP001 with your tank design, operations, and inspections. Get a prioritized action plan and templates.

What Are The OSHA Requirements For Confined Space Entry In Storage Tanks?

- Contains or may contain a hazardous atmosphere.

- Contains material with potential to engulf entrants.

- Has inwardly converging walls or floors that could trap or asphyxiate.

Tank entry under texas aboveground storage tank regulations and texas above ground storage tank regulations follows OSHA’s permit system designated supervisor, trained entrants, and an attendant; pre-entry atmospheric testing and continuous monitoring, ventilation, lockout/tagout, and isolation. Calibrated meters, personal protection equipment, and retrieval lines. Reliable communication, and a rehearsed rescue plan with timely EMS coordination. Permits document hazards, controls, time limits, and authorization, and are canceled when conditions change. Maintain records and post permits at entry points.

What Is Considered An AST?

- Under texas above-ground storage tank regulations and texas above ground storage tank regulations, an AST stores liquids above grade with visible, inspectable components.

- Protected ASTs feature integral fire-resistive assemblies or double walls; ordinary ASTs rely on single-wall construction with external fire protection.

- Protected ASTs feature integral fire-resistive assemblies or double walls; ordinary ASTs rely on single-wall construction with external fire protection.

- Acceptable designs cover atmospheric tanks to low-pressure vessels, typically up to 15 psig, with code-compliant foundations, vents, and overfill control.

- Primary types: fixed-roof cylindrical, internal/external floating-roof, and horizontal/vertical shop-fabricated tanks used for petroleum and chemicals.

What Is The Air Gap In A Storage Tank?

An air gap is a vertical separation between a discharge point and the receiving liquid’s flood rim. In AST operations, it interrupts siphon paths and prevents backflow, cross-connection, and contamination. This physical break supports spill control and product integrity under texas above-ground storage tank regulations, complementing valves and checks.

Air gaps are critical during fuel deliveries, transfers to day tanks or generators, washdowns, and temporary hookups near drains or water. When handling dissimilar products or potable water lines, an air gap under texas above ground storage tank regulations reduces mixing risk, simplifies decontamination, and strengthens compliance audits and documentation significantly.

What Is The Inspection Code For Storage Tanks?

Under texas above-ground storage tank regulations and texas above ground storage tank regulations, AST inspection follows a defined process. Establish scope, review history, classify tank type, perform routine visual checks, external examinations, and internal inspections as warranted. Verify foundations, shell, roof, appurtenances, and secondary containment; assess corrosion, settlement, venting, and overfill protection. Use calibrated NDE, thickness surveys, and leak tests. Document findings, calculate remaining life, set next intervals, and correct deficiencies through repair, alteration, or decommissioning, with inspectors overseeing work.

| Code/Standard | Primary Application |

|---|---|

| API 653 | In service inspection, repair, alteration and reconstruction of field-erected ASTs |

| STI SP001 | Inspection for shop-fabricated tanks, portable containers, and associated secondary containment. |

| API 650 | Design and construction basis for welded oil storage tanks; informs acceptance criteria. |

| API 570 | Inspection and repair of piping, valves, and flanges connected to AST systems. |

| API 510 | Inspection of pressure vessels supporting processes adjacent to AST installations. |

| API 579-1 / ASME FFS-1 | Fitness-for-Service assessments, remaining life, and run-repair-replace decisions. |

| Note | Applied alongside texas above-ground storage tank regulations and texas above ground storage tank regulations for compliance. |

What Are Five OSHA Safety Requirements For Storage Tank Operations?

Integrating OSHA controls into AST programs ensures hazard reduction, training, and documentation alongside texas above-ground storage tank regulations and texas above ground storage tank regulations. Embedding requirements in procedures streamlines audits, prevents injuries, aligns contractor work, and improves emergency readiness. Effective integration turns routine operations into dependable compliance every day.

- 29 CFR 1910.106: flammable liquids, tank design, grounding/bonding, ventilation, ignition control.

- 29 CFR 1910.1200: Hazard Communication, labels, SDS, training, written program.

- 29 CFR 1910.146: permit required for confined spaces permits, monitoring, rescue.

- 29 CFR 1910.147: Lockout/Tagout, energy isolation for pumps and transfer systems.

- 29 CFR 1910.38/1910.157: emergency action plans, drills, fire extinguishers.

What Areas Does OSHA Not Cover In Storage Tank Operations?

OSHA does not cover the self-employed; immediate family members of farm employers; or public-sector workers in Texas without a state plan. Certain industries fall outside OSHA’s primary jurisdiction: mining (MSHA), over-the-road transportation in transit (DOT), and most maritime operations under the U.S. Coast Guard.

In storage-tank contexts, environmental and fire requirements still apply. EPA’s SPCC, PHMSA pipeline rules, NFPA codes, local fire marshals, and TCEQ enforce controls alongside texas above-ground storage tank regulations and texas above ground storage tank regulations. Depending on site activities, Coast Guard, MSHA, or DOT may govern operations, inspections, or incident response where OSHA lacks authority.