Key Takeaways

- The types of generator vary by fuel, output, and intended application.

- Understanding generator types helps match power supply to actual needs.

- AC and DC types of electric generators have different use cases.

- Examples of generators range from portable camping units to industrial 3-phase systems.

- Selecting the right generator type depends on power demands, mobility, and budget.

Table of Contents

Types Of Generator

Internet users search for types of generators in several ways. Some people search generator types, types of generators, and different kinds of generators. All these different ways of searching show how much people need this information and how they look for it online, and that behavior of internet users influences how we write guides such as this one. While all these phrases essentially are trying to find devices that convert mechanical energy into electrical energy, the little differences in phrasing will lead the readers to focus on different categories, such as types of electric generators or types of power generators. When broad terminologies like these are used, they ensure that readers and researchers find a large pool of information for their consideration, whether they need different types of generators for their homes or for business purposes.

At Elan Fuels, when we write these kinds of guides, our goal is to help you find the right kind of generator. And we have an interactive tool that you can use to match you with the kind of generator type you want in a way that’s very straightforward. And very beginner-friendly. If you head over to our website, you can find it.

What Are Examples Of Generators?

Examples of generators are extensible. Some examples of generators include portable gasoline units for camping, standby diesel motors for homes, and large gas turbine setups for industrial facilities. Generator examples also extend to specific RV units, marine generators used by boats, and hybrid solar-powered models.

For the sake of functionality, examples of electric generators can be categorized by how they are fueled, such as propane, natural gas, or renewable sources. The diversity of different generators ensures there’s a solution for almost every energy need, be it examples of electric generators for emergency home backups, or larger generators that run continuously in industrial settings.

Confused Between Generator Types? We’ll Help You Decide.

From AC vs. DC to inverter vs. standby, choosing the wrong generator can cost more in fuel, repairs, and performance. Take our expert quiz to get a generator recommendation tailored to your exact needs.

What Is The Difference Between AC And DC Generators?

AC stands for alternating current, which reverses direction periodically. AC generator types are ideal for homes, businesses, and general electrical grids. On the other hand, there are DC (direct current) types of electrical generators, which produce direct current that flows in a single direction. These ones are perfect for charging batteries, for welding, and low voltage usage. Knowing what you need, be it AC or DC generator types, depends on the device or devices you plan to power. For long distance power transmissions, AC units are better. While for equipment that require precision, DC units are more suitable. By understanding these differences, you will be able to select the correct type of generator for your specific need.

We can help you figure out the generator that best suits your project if you would take our free buyer quiz. This quiz is designed by experts and when you answer them, you will have recommendations based on your specific needs.

Which Type Of Generator Is Best For You?

To choose the right type of generator, you have to assess your needs. If you’re going to use your generator as a backup for your home’s electricity, standby diesel or natural gas generator types are better options and they offer good performance. If you’re going out camping or if you need the generator for mobile use, you need a lightweight inverter model which are quite popular types of power generators. If you’re in a small business, single-phase types of electrical generators are often suitable, but for industrial users, they may require three-phase units.

There are other factors that you need to consider when trying to decide the right type of generator, such as the cost of fuel, the frequency of maintenance, noise levels, and noise levels. The best generator type is the one that meets your exact power demand without overspending and without other inconveniences.

Buying a Generator? Know What Tier You Need.

Environmental laws can impact what type of generator you’re allowed to use. Learn the difference between Tier 1, Tier 3, and Tier 4—and how it affects your power, cost, and legal compliance.

What Are Other Specialized Or Less Common Generator Types?

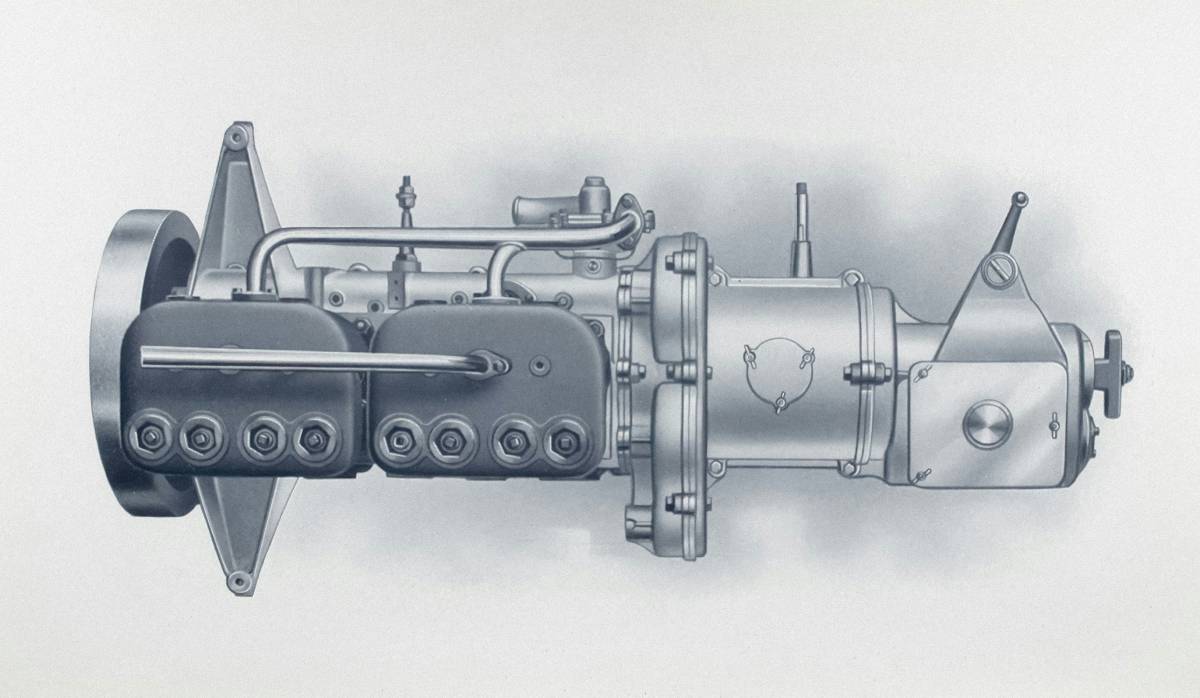

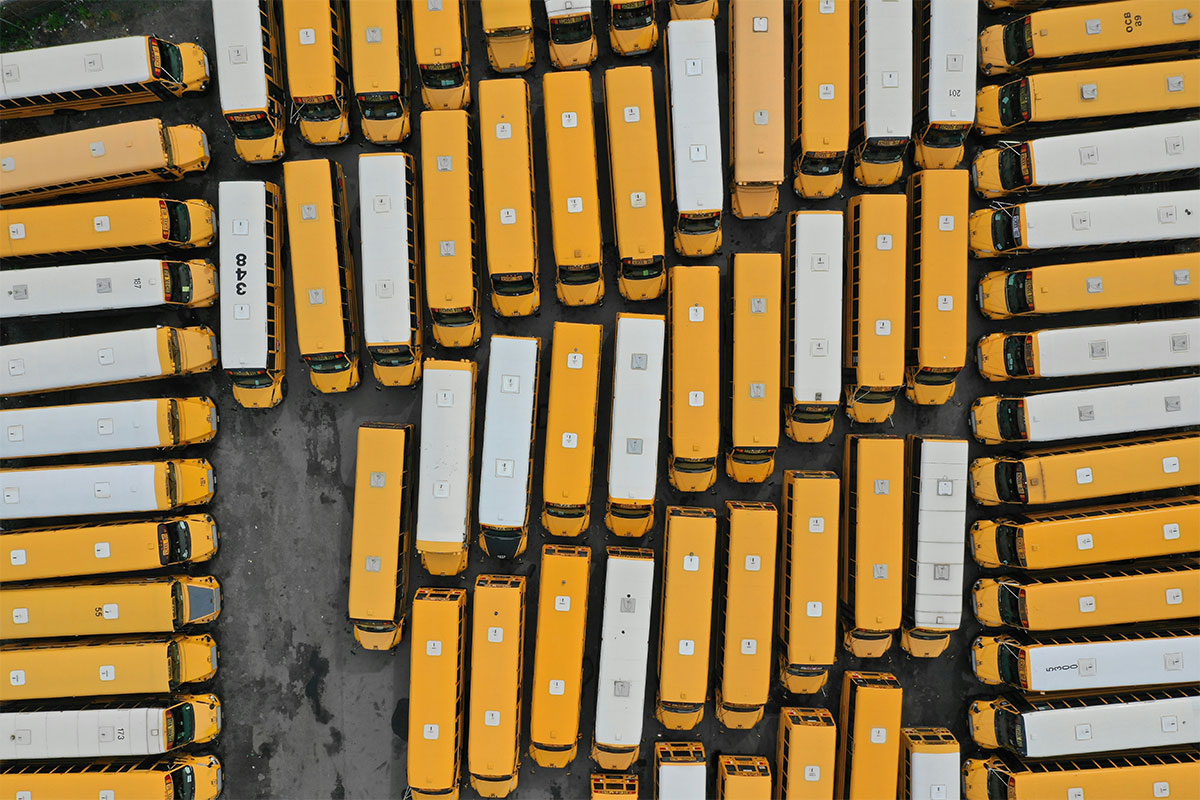

Beyond the types of generators that are common, there are other ones that are more niche like dynamos which are older types of generators that produce direct current. There are also canopy generators that have noise reduction. They are turbine power generators for large-scale continuous use. In some trucks and buses, there are also different type of generators called vehicular generators. These provide on-board electricity in the buses.

Permanent standby generators are also specialized categories in the different kinds of generators These are designed for facilities that cannot afford any downtime.

What Are The Types Of Electric Generators?

Types of electric generators are in two categories, AC and DC. AC types of generators are used mostly to power grids and in households, while DC types of generators are mostly used in battery-based or very specialized industrial usages.

The two work by converting mechanical energy to electrical energy through electromagnetic induction. The types of power generators used in industrial settings can handle massive loads while the residential units focus on convenience and reliability.

What Are The Most Common Questions About Generator Types?

One of the most common questions about generators is “how many types of generators exist.” The answer to that question depends on what classification method is being used, whether it’s electrical output, fuel type, or application. We mostly use mechanical, electrical, and electromagnetic as the terminologies to qualify generator types. Another question that is repeated when doing research about generators is “what are the three types of generators”. Typically, we have portable, standby, and inverter models. These questions showcase the differences between generator types as broad categories and generator examples as specified models.

Power Up With the Right Generator Type

Not all generators are created equal. Whether you’re powering a campsite or an industrial site, we’ll break down the fuel types, AC/DC differences, and performance specs that matter most.

What Are The Applications Of 3-Phase And Industrial Generators?

Large systems, such as factories, data centers, hospitals, require continuous, reliable electricity to support operations that are critical and whose downtime can be fatal or have heavy consequences. This is where three-phase generator types are used. Unlike single-phase units, three-phase types of electrical generators provide power very efficiently and equally across several circuits. This makes them suitable for heavy machinery and sensitive electrical systems. Industries with high power output demands often use these types of power generators to assure operational stability and meet high standards of safety and performance.

In high-load, high-reliability scenarios, such as construction and mining, three-phase generator types provide the power and robustness that are necessary for the demands of the equipment used in these industries. For example, in mining, these kinds of generators are used to make sure that there is constant electricity in remote locations where the electricity grid rarely covers in an unreliable manner. Construction sites also use portable three-phase generators to power large tools and lighting systems. The longevity and power balance of these generator types makes them highly suitable in environments where constant electricity is rare but very needed.

To differentiate between single-phase and three-phase generators, you need to understand how electrical power is distributed in them. For single-phase types of electric generators, the power is supplied through one alternating current and this is suitable for small loads such as homes, very light operation businesses. While three-phase generators operate using three separate alternating current offsets in phase. These provide steady and high power output. The capacity to provide and sustain high power output of three-phase units makes them the most suitable choice in industrial usage that require a lot of power, great efficiency and low wear. These three-phase generators provide the most wear on equipment compared to the single-phase generator types.

What Is A Tier 3 Generator And Why Does It Matter?

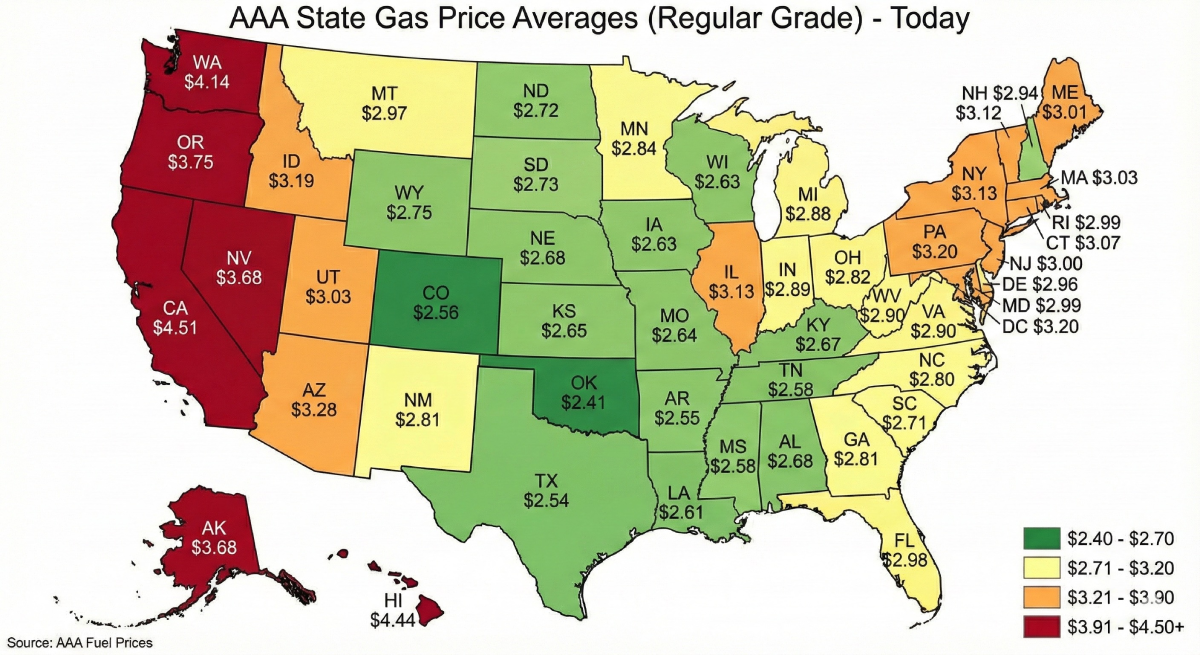

In regulated markets, when you’re trying to buy a generator, it’s not just about power. You also need to make sure you’re meeting the necessary legal requirements. A Tier 3 generation type is tailored to the U.S. Environmental Protection Agency emission standards, which is aimed at reducing the amount of harmful pollutants emitted into the environment. These types of power generators are used mostly in industries that seek to comply with environmental regulations. Compared with Tier 1 or Tier 4, Tier 3 represents a middle ground which offers cleaner operations without the high cost of Tier 4 compliance. Below is a table that compares Tier 1, Tier 3, and Tier 4 compliance for you to understand better and make a more informed choice.

| Regulatory Tier | Emission Standards Focus | NOx Emission Limits (g/kWh) | PM (Particulate Matter) Limits (g/kWh) | Typical Applications | Key Features and Importance |

|---|---|---|---|---|---|

| Tier 1 | The earliest EPA standards for emissions control, focusing on reducing the most harmful pollutants from diesel engines but allowing relatively higher emissions. These standards aimed to introduce basic pollution controls on industrial equipment. | 7.0 | 0.4 | Older industrial and construction equipment, less regulated areas, and legacy fleets still in operation. | Tier 1 allows higher emissions compared to later tiers. It serves as a baseline for cleaner engine design but is less environmentally friendly. Suitable where emissions regulations are minimal. |

| Tier 3 | Represents a moderate emissions reduction standard that balances environmental concerns and operational costs. It mandates a significant reduction in nitrogen oxides (NOx) and particulate matter (PM) emissions compared to Tier 1. | 3.5 | 0.2 | Widely used in construction, mining, and industrial generators that must meet moderate EPA emission requirements. | Tier 3 is the most common regulatory level for many industries. It enables cleaner operation with fewer pollutants while keeping technology and compliance costs moderate. |

| Tier 4 | The most stringent EPA emissions standards currently in force. It requires the lowest emissions of NOx and PM, often achieved through advanced technologies such as selective catalytic reduction (SCR) and diesel particulate filters (DPF). | less than 0.4 | Less than 0.01 | New industrial and commercial generators, environmentally sensitive sites, and locations with strict air quality regulations. | Tier 4 compliance involves sophisticated emission control technology, resulting in the cleanest engines available. It significantly reduces pollutants but at a higher upfront and maintenance cost. |

Additionally, nitrogen oxides (NOx) and particulate matter (PM) are two key pollutants regulated under these tiers. NOx contributes to smog and respiratory problems, while PM includes fine particles that can penetrate deep into the lungs. The lower the emission limits in the tier, the cleaner and more environmentally friendly the engine is. Many industries strive to comply with Tier 3 or Tier 4 standards to reduce environmental impact and adhere to regulations.