Key Takeaways

- Hospital backup generator requirements protect life safety, critical care, diagnostics, and essential building systems during any hospital power outage.

- NFPA 99, NFPA 101, NFPA 110, and NFPA 37 shape hospital emergency power systems design, installation, and testing.

- Multiple hospital backup generators and N plus 1 designs improve redundancy and compliance.

- Runtime depends on NFPA class, fuel strategy, and maintenance, not only unit size.

- Fuel choice and automatic transfer systems must align with regulation and documented hospital backup power strategies.

Table of Contents

Hospital Backup Generator Requirements

Hospital backup generator requirements ensure that crucial clinical services continue operating during any power outage. Building codes classify the hospital generator as part of an Essential Electrical System. This system must support life safety critical care diagnostics and essential building functions. Effective hospital emergency power must start automatically and carry necessary loads within seconds. It must also operate for specified minimum durations usually several hours or more.

Regulators require protective coverage for critical areas. These areas include operating rooms intensive care units emergency departments and fire protection systems. Coverage also extends to alarms communications specific HVAC systems and medication storage. Compliant designs integrate the hospital power generator with fuel systems transfer switches and selective coordination. They also require monitoring testing and documented maintenance programs. These programs verify safe hospital backup power during emergencies. Compliance aligns with NFPA and Joint Commission criteria.

What Is The Minimum Starting Requirement Of An Emergency Generator?

NFPA 110 mandates that Level 1 emergency generators for hospitals supply power to critical loads within 10seconds of a utility failure. The compliant hospital emergency generator must automatically sense the failure, start immediately, and transfer prioritized circuits. This ensures protection for ventilators surgical suites monitoring and egress lighting during power outages.

What Is The NFPA Code For Generators?

These are some of the key NFPA standards that govern hospital backup generator design and hospital emergency power systems.

| Code | Focus | Hospital application |

|---|---|---|

| NFPA 99 | Health care facilities code | Defines Essential Electrical Systems and nfpa 99 generator requirements for critical branches. |

| NFPA 101 | Life safety code | Links egress lighting and protection during hospital power outage to reliable backup power. |

| NFPA 110 | Emergency power supply systems | Sets start time, performance, and testing for emergency generators for hospitals. |

| NFPA 37 | Stationary engines | Controls engine siting, fuel piping, and fire safety for generators for hospitals. |

In order to get credibly accredited, hospital emergency systems must adhere to these codes.

Unsure If Your Hospital Meets NFPA Generator Standards?

From NFPA 99 and 110 to Type 1 vs Type 2 branches, one missed detail can threaten accreditation and patient safety. Use this guide to review your Essential Electrical System, confirm 10-second transfer compliance, and align fuel, ATS, and documentation with current code expectations.

What Are NFPA 99 Hospital Generator Requirements?

Essential Electrical Systems are classified into Type 1 and Type 2 by the NFPA 99 codes, assigning branches that hospital backup generators must support. Type 1 covers high risk patient care areas and demands highly reliable hospital backup power. Type 2 serves lower risk spaces with reduced requirements. Together they define how hospital emergency power systems prioritize life safety, critical care, and essential equipment.

What Is NFPA 110 And How Does It Regulate Emergency Generators?

NFPA 110 governs performance of hospital emergency power systems using hospital backup generators as Emergency Power Supply Systems. For Level 1 applications it requires power delivery to critical loads within 10 seconds and defines run time classes. It also sets testing, maintenance, and fuel expectations so each hospital emergency generator reliably starts, carries load, and stays online during utility failure.

Does NFPA 37 Apply To Generators In Hospitals?

NFPA 37 applies to stationary combustion engines, so it is relevant when hospitals install engine driven hospital generators or generators for hospitals near buildings. While NFPA 99 and NFPA 110 address hospital emergency power systems, NFPA 37 focuses on fire and explosion risk from engines and fuel. It covers enclosure construction, required clearances, ventilation, fuel piping, spill control, and protection from exposures. For any engine based hospital backup generator, designers must apply NFPA 37 together with mechanical, fuel, and building codes so that emergency power equipment does not introduce unacceptable hazards to patients, staff, or infrastructure while delivering dependable hospital backup power. Coordinated application of these standards supports safe siting, long term reliability, and regulatory approval for critical projects everywhere.

How Many Backup Generators Does A Hospital Need?

- The number of hospital backup generators depends on facility size, care level, and redundancy goals.

- Large tertiary centers often install multiple units so one hospital generator can be offline while others carry required loads.

- Separate units may support life safety, critical, and equipment branches where hospital emergency power systems segregation is required.

- Engineering studies determine diversified load, growth projections, and N plus 1 configurations.

- Regulators and insurers expect capacity that survives single failures without losing essential functions.

- Practical planning asks how many backup generators does a hospital have today, and what capacity is needed tomorrow to protect operations.

- Consult qualified engineers to size emergency generators for hospitals accurately, document justification for oversight bodies.

Not Confident Your Generators Are Sized And Redundant Enough?

If a single failure can take critical care offline, your configuration is not truly N+1. Learn how to calculate essential loads, plan for growth, and determine how many generators your facility really needs, without overspending or risking outages in ORs, ICUs, and EDs.

How Long Do Hospital Backup Generators Last?

Hospital backup generator run time during an outage is a key consideration. NFPA 110 and fuel storage regulations mandate at least several hours of continuous power. Many facilities plan for 24 hours or longer. The service life of hospital generators also matters. With proper preventive maintenance, good fuel, regular testing, and timely overhauls, a hospital backup generator can last reliably for 20 to 30 years. These generators support compliant emergency power systems in critical clinical settings. Engine hours, loading profiles, ambient conditions, and following manufacturer instructions greatly affect lifespan. Asset managers must track performance and schedule replacements before reliability decreases or regulatory checks find unacceptable risk.

What Kind Of Backup Generators Do Hospitals Use?

Hospitals typically select diesel emergency generators for their reliability, power density, and established service networks. Natural gas or dual fuel options are sometimes chosen when the fuel supply is reliable and emission standards are strict. Large hospital campuses often use multiple generators in a coordinated system. While portable units offer supplementary power for temporary needs or remote clinics, core operations depend on permanent installations and robust emergency power systems. These fixed systems must comply with regulations and reliably address clinical risks. Generator selection requires careful consideration of critical load needs acoustic limitations footprint restrictions refueling logistics and alignment with regulatory requirements for hospital backup power.

How Do You Calculate Backup Power Requirements For A Hospital?

Sizing a hospital’s emergency generator starts with listing all essential loads that must operate during a power outage. These loads include life safety equipment critical care systems diagnostics communications HVAC and essential support services. Engineers organize these loads by Essential Electrical System branches. They calculate the running and starting power requirements in kilowatts and kilovolt amps applying necessary diversity and growth factors. The selected generator must meet the calculated capacity along with specific hospital emergency power requirements for voltage frequency and step loading. Adherence to NFPA 99 and NFPA 110 guidelines is crucial for correct sizing and distribution. Complete documentation supports funding satisfies regulatory authorities and minimizes lifecycle risk. Specialist consultants should review the results before purchasing equipment. This prevents overloads blackouts and unsafe operation margins during stress conditions.

How Often Do Hospital Generators Need To Be Tested?

- NFPA 110 and accrediting bodies require structured testing of hospital backup generators.

- Perform weekly visual inspections of each hospital generator, fuel system, and control panel.

- Conduct monthly load tests where hospital emergency power systems run under load for at least 30 minutes.

- Complete annual extended load tests that prove sustained hospital backup power performance.

- Every 36 months many authorities expect multi hour tests at defined load levels.

- Record all results, deficiencies, fuel issues, and corrective actions.

- Failure to test emergency generators for hospitals can jeopardize accreditation, coverage, and patient safety obligations.

- Use qualified technicians, follow manufacturers instructions, and integrate testing into a documented reliability program reviewed during compliance surveys, inspections, and audits.

Is Your Testing, Fuel, And ATS Strategy Survey-Ready?

Weekly inspections, monthly load tests, multi-year run tests, fuel quality, and ATS performance all decide if your system works when it counts. Turn complex testing rules into a clear schedule that satisfies accrediting bodies and keeps your emergency power reliable.

How Do Automatic Switches Work In Healthcare Facilities?

Automatic transfer switches are the essential link between normal utility power and hospital emergency power systems. When sensors detect a power failure the switch tells the hospital emergency generator to start. It waits until the voltage and frequency are stable. Then it transfers specific circuits to the alternate source.

When utility power is restored and stable the switch automatically returns the load without human input. Properly rated ATS units must support selective coordination fast transfer times and a clear status display. Integrated testing helps ensure hospital backup generators and distribution respond correctly. This minimizes critical service interruptions and provides safe predictable transitions. Engineers must correctly size label and maintain these switches to meet generator and accreditation rules.

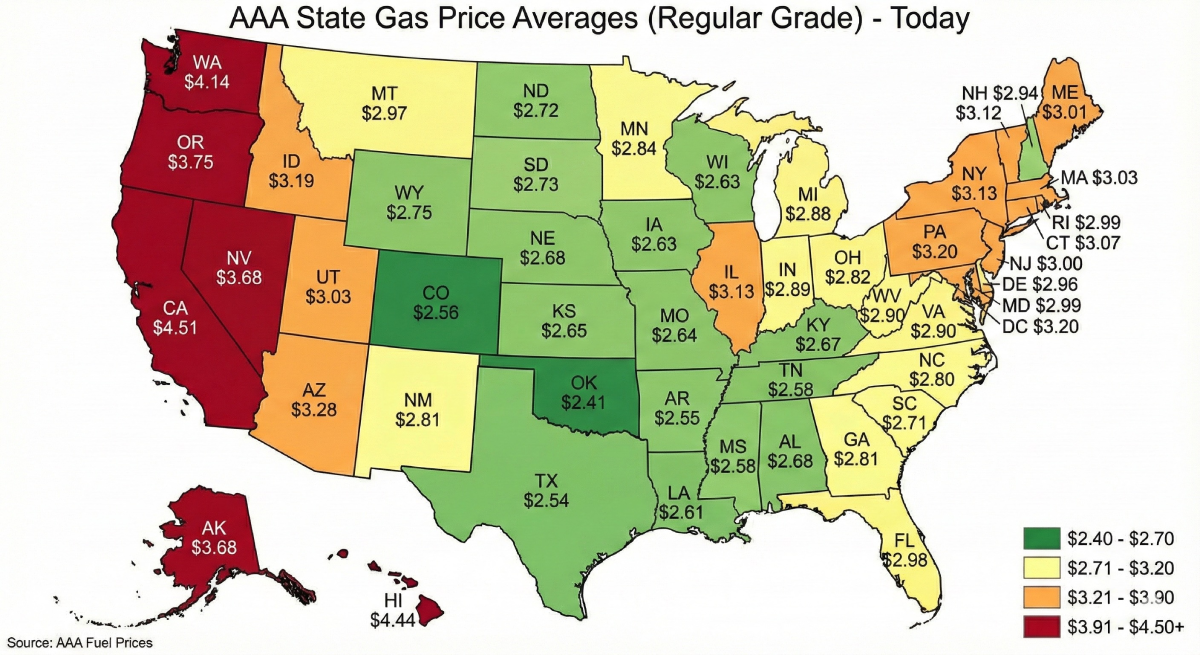

What Generator Fuel Sources Are Used In Hospitals?

Hospitals choose fuels that sustain dependable hospital backup power and compliant hospital emergency power systems.

| Fuel type | Key benefit | Key limitation |

|---|---|---|

| Diesel | Proven choice for hospital backup generator sets | Needs on site storage and conditioning |

| Natural gas | Continuous supply for hospital generators | Dependent on pipeline availability and pressure |

| Propane | Option where gas is unavailable | Bulk storage and delivery planning |

| Hybrid or bi fuel | Flexibility for each generator for hospital | Higher complexity and cost |

Align choices with hospital backup generator requirements and accreditation. Consider runtime goals, limits, emissions targets, and fuel security when planning.

What Is The Alternative To A Backup Generator In Hospitals?

Options for hospital power outside of traditional generators include battery storage, onsite renewable energy with microgrids, and fuel cells. These technologies offer benefits like reduced emissions and noise. They also provide immediate power stability during a hospital outage.

However, high current costs, limited operating duration, and technology risks mean these systems usually support the main generator rather than replacing it. Hospital emergency power requirements still mandate high quality engine based backup power as the main safeguard. Batteries and smart controls can improve power quality for sensitive equipment and smooth transitions. Design teams should thoroughly test hybrid systems and confirm long duration capability before reducing conventional generator coverage.

What Is The Difference Between Type 1 And Type 2 Essential Electrical Systems?

Type 1 Essential Electrical Systems support the highest risk patient care areas, including operating rooms, ICUs, and emergency departments, where any interruption is unacceptable. Here, hospital emergency power systems and hospital backup generator requirements are most stringent, demanding rapid transfer, redundancy, and segregation. Type 2 systems serve lower risk areas where brief interruptions are permitted. They still rely on hospital backup generators but with reduced capacity and segmentation needs. Understanding these categories from NFPA 99 helps designers assign hospital backup power correctly, answer regulators who ask if hospitals have generators that match risk, and ensure resources focus where loss of power would be catastrophic. Clear documentation of Type classifications also simplifies maintenance planning and future hospital emergency power requirements reviews.