Key Takeaways

- Always follow OSHA, NFPA, and EPA rules for fuel storage on construction sites.

- Secure tanks with locking devices to prevent fuel theft or sabotage incidents.

- Diesel safety includes distance rules, compatible tanks, and flame-proof storage zones.

- Use trained staff and proper PPE when storing fuel on construction sites.

- Document all inspections, spills, and deliveries for full legal and insurance protection.

Table of Contents

Fuel Storage On Construction Sites

During construction projects, fuel storage on construction sites is used to support generators, excavators, other construction equipment and fuel stations. The presence of fuel storage on construction sites is a productivity hack as it helps reduce equipment idling, reduces delays and prevents crucial processes that require heavy machine output from witnessing long downtimes. However, storing fuel on construction sites also has its fair share of risks. Fuel on construction, if not properly stored sites may leak, causing damage to the environment, they can cause fires, contamination and it also attracts thieves. Common storage tools include UN/DOT-approved tanks, secondary containment basins, and vapor control systems. All containers must be compatible with stored fuel types and clearly labeled. OSHA and NFPA codes stress storing fuel away from open flames or mechanical equipment. Choose locations that are flat, shaded, and protected from weather. Use safety signage, personal protection zones, and spill kits.

Secure your site with our tank solutions to tank solutions to reduce risks and stay compliant.

Why Is The Location Of Fuel Storage Crucial On Construction Sites?

Proper fuel storage on construction sites is mandatory as it plays a very crucial role in site safety. If the fuel stored isn’t properly located on construction sites, it can lead to fire accidents, ventilation issues and it can also slow work on the site by blocking emergency routes.

OSHA mandates that storing fuel on a construction site must prioritize access for emergency responders and spill containment. Tanks have to be grounded, elevated and be located very far away from ignition points and traffic areas. They must also be away from walk ways, unguarded slopes, welding areas and storm drains.They also require well ventilated zones, they must be at least 40 feet away from residential buildings or materials that can burn. The planning of the sites should have incorporated exits for emergencies, signage points and inspection routes. The tanks should also be equipped with natural barriers, berms and containment walls that further protect against leaks.Carefully reviewing fire code buffer zones before placing tanks helps avoid accidents and fines.

Worried About Fuel Storage Compliance? Don’t Risk Costly Fines.

Fuel violations can shut down your project fast. Use our free OSHA & EPA checklist to stay compliant with tank spacing, containment, labeling, and emergency protocols.

Construction Site Fueling And Storage Best Practices

The following best practices for fuel storage on construction sites will prevent accidents and improve efficiency.

- Use OSHA-compliant tanks with flame arresters and anti-overflow valves when storing fuel on construction sites.

- Segregate storage from live work zones and clearly mark hazard perimeters.

- Keep a standard fueling checklist which includes inspecting hoses and tanks daily, shutting down engines before fueling, always keeping a fire extinguisher nearby, having gloves and goggles on and continuously documenting fuel volumes.

- Avoid refueling during extreme heat or near open equipment.

- Spill response kits must be readily available, and fuel deliveries should be logged and supervised. Trained personnel must handle all transfers and post fueling signs prominently.

- A checklist sample should also involve checking tank level, verifying valve seals, confirming PPE use and logging refuel events.

OSHA Regulations And Legal Compliance For Fuel Storage

The rules for tank material, pressure relief valves, distance from buildings, and fire protection are contained in 29 CFR 1926.152 of OSHA’s regulation. Violations for improperly storing fuel on construction sites will lead to fines, work stoppages, and even lawsuits. For example, failing to ground portable tanks or skipping leak inspections are frequent violations that attract sanctions. It is the responsibility of employers that all workers are trained on handling fuel, and they must also ensure that recordings of inspections, maintenance and refuelling are logged. OSHA also mandates secondary containment systems for certain volumes.

Stay audit-ready and avoid costly penalties by accessing our OSHA checklist for contractors.

Need a Safer Way to Store Fuel On-Site?

Our flame-resistant, OSHA-certified tanks come equipped with anti-theft locks, overfill alarms, and spill-proof valves—ideal for construction environments.

Environmental Regulations Compliance For Fuel Storage

Apart from OSHA regulation, the EPA also has laws that enforce environmental protection for fuel storage on construction sites such as the Spill Prevention, Control, and Countermeasure (SPCC) Rule. SPCC plans are mandatory if a site stores more than 1,320 gallons aboveground.

Runoff into waterways, storm drains and soil have to be avoided when storing fuel on construction sites, firms must prevent runoff into waterways, storm drains, or soil. Building spill berms, secondary containment, and oil/water separators are good ways to ensure that runoffs don’t happen. Staff training programs must cover emergency response protocols, leak detection techniques, and spill reporting. This training has to be done year to refresh workers and update their knowledge if necessary.

Records of inspections, incidents, and maintenance have to be written. Emergency contact lists and spill flow diagrams should be visibly posted around prominent places on the site. Non-compliance to the regulation of the EPA can lead to huge fines and even losing your building permit.

Diesel Fuel Storage Safety Rules And Distance Guidelines

Diesel is the most used fuel for heavy equipment and because of this, its storage has very tight protocols that construction projects have to abide by.

For fuel storage on construction sites, diesel tanks must meet NFPA 30 and OSHA requirements. When storing fuel on construction sites, position diesel tanks at least 25 feet from ignition sources, 40 feet from structures, and on stable, leak-proof foundations.

Only tanks specifically built for diesel storage with flame catchers, overfill alarm systems and emergency shutdown mechanisms should be used. Diesel tanks must be labeled clearly and isolated from other fuel types. They also have to be grounded to prevent static buildup.

Diesel must be stored in cool, shaded areas to reduce vapor pressure buildup from evaporation. To make sure your tanks are compliant and compatible with diesel storage, EPA and Department of Transport certifications.

Is Your Team Trained on Diesel Storage Safety?

From tank grounding to fire buffer zones, proper training prevents spills and protects lives. Access our quick-start guide for contractors storing diesel on job sites.

NFPA Codes And Fuel Safety Guidelines

NFPA 30 is the regulation that governs flammable and combustible liquid storage, offering vital guidance for fuel storage on construction sites.

In storing fuel on a construction site, it is important to control ignition by installing flame arresters, grounding the tanks, having vapor vents, and approved signage. Tanks must be constructed with NFPA-approved materials and surrounded by containment barriers.

The tanks must be bonded and grounded to prevent static buildup. Only explosion proof equipment should be used close to fuel tanks.

Emergency shutoff switches, fire extinguishers, and spill response kits must be within close reach. Inspections after severe weather events are also part of NFPA requirements for having storage on construction sites. All tanks must have large and clear “flammable” and “no smoking” labels and warnings and employers must make sure fire risk assessments and updated response plans are available and are specific to their construction sites.

Key Safety Protocols For Fuel Storage

Following mandatory safety steps when managing fuel storage on construction sites protects both people and equipment. Only trained staff should be allowed on sites that store fuel. You should also make sure they have and use personal protection equipment like gloves, goggles, and fire-retardant clothing worn at all times.

Only the fuel you need should be stored on the site, no more. As excess fuel on the site increases risks of hazards. Emergency shutdown protocols must be clearly defined, visibly posted and practiced several times to the point of mastery by site workers. Install flameproof lighting, define no-smoke zones, and containment pallets. The plan to respond to leaks must be clearly written in advance, every refuelling event must be logged and you must test for vapor leaks regularly. Don’t put different fuel types in the same tank and ban all open flames around the tanks, only spark-proof tools should come near.

On-Site Fuel Delivery And Refueling Practices

To keep the project moving and not cause unnecessary down times, only DOT approved vehicles which have the proper documentation should be used to deliver fuel at hours with the lowest site activity.

Refueling cannot be random, it must be well planned and executed.

Supervise all deliveries and verify volume, fuel type, and labeling. Set up spill zones with absorbent mats and shut off every engine before refueling. Workers must be trained to respond to spills, fires, or fuel exposure. Keep hose fittings secure and label storage tanks clearly. Anti-theft systems and tamper-proof caps help prevent theft. Use visual emergency signage and coordinate with vendors for compliance checks. Log all activity to track inventory and spot irregularities.

Preventing Fuel Theft And Vandalism On Construction Sites

The more fuel there is on a construction, the more theft becomes a serious concern with fuel storage on construction sites. The thieves always wait for hours when the crew isn’t working actively to strike.

To ensure storage that is safe from thieves, use locking tank caps, motion triggered alarms and floodlights to track suspicious movements that may happen around the storage tanks. You can also install tamper-proof seals and RFID tracking systems for fuel inventory. Frequent audits help detect suspicious activity. Use perimeter fencing and surveillance cameras to monitor tank zones. Cap sensors can alert staff if tanks are being siphoned. All access points should be reinforced, and only authorized personnel should handle keys. Keep theft logs and investigate anomalies immediately.

Fuel Tank Placement And Ventilation Rules

Placing fuel tanks strategically on construction sites helps reduce the possibility of hazards and ensures compliance. For fuel storage on construction sides, the tanks have to be at least 40 feet away from sources of ignition like generators and welding stations. When storing fuel on construction sites, maintain adequate spacing and fire buffer zones. Use vapor dispersion modeling to ensure gases don’t accumulate.

Install passive or mechanical ventilation systems in tank areas, fuel tanks shouldn’t be stored in enclosed or low-lying areas, check local building codes for zoning-specific requirements and make sure there is unobstructed access for fire response teams. Include signage for emergency shutoff valves and ventilation system maintenance schedules.

Fuel Tank Inspection, Maintenance And Monitoring

Routine inspection prevents leaks, contamination, and system failure. For fuel storage on construction sites, tanks must be inspected weekly and after storms or accidents. When storing fuel on construction sites, check for corrosion, loose fittings, and blocked vents. Use dipstick tests and digital level sensors to monitor capacity. Gauge readings should match delivery logs. Inspect containment basins for water or sediment. Schedule professional maintenance bi-annually and flush tanks regularly. Wear PPE when cleaning tanks. Integrate monitoring systems with theft detection tools. Keep records of every inspection, including inspector name, date, and corrective actions taken.

Fuel Type Selection And Storage Capacity Planning

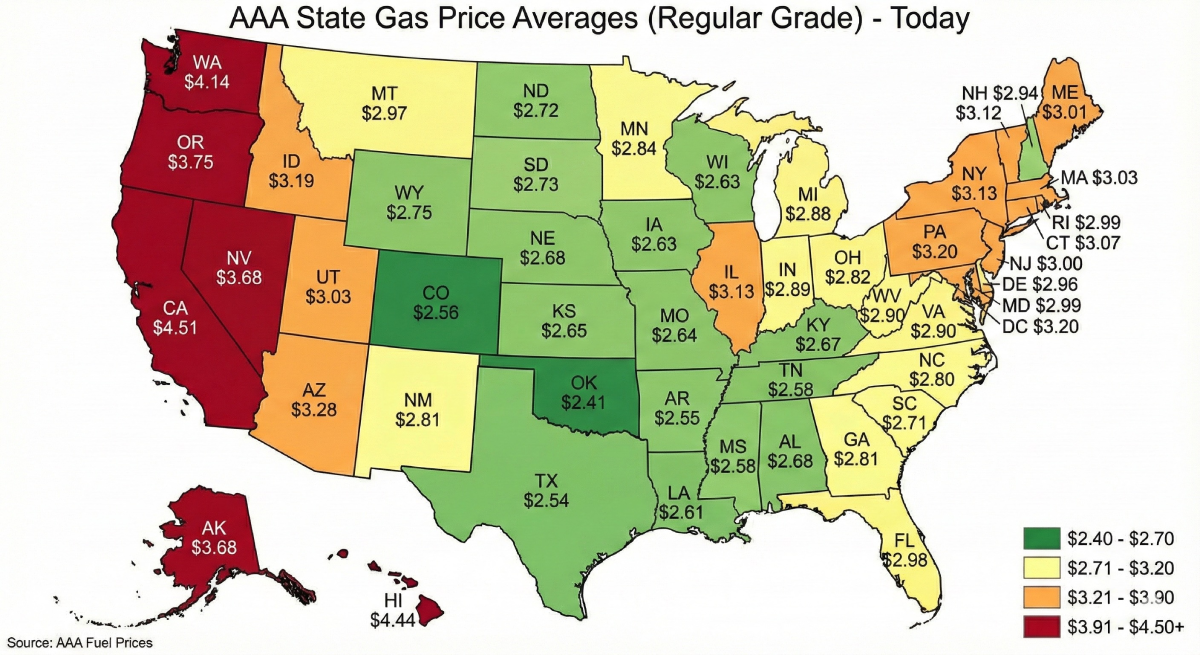

Choosing the right fuel to store on a construction site has impacts on cost, efficiency, and compliance to environmental regulations.

For fuel storage on construction sites, diesel is most common because it is mostly used in heavy duty machines, renewable diesel is also gaining popularity for its cleaner emissions profile.

It is important to check the compatibility of each storage tank to the storage stored as some fuels like gasoline, biodiesel and other renewable blends can need different materials for storage. Plan capacity based on daily use, equipment size, and delivery schedules.

Avoid oversizing tanks, which can increase exposure risks and costs. Ensure compliance with EPA storage volume thresholds and secondary containment rules.

How To Calculate Fuel Storage Capacity

Fuel capacity planning involves daily use, emergencies, and delivery cycle timing. When planning fuel storage on construction sites, calculate expected daily consumption per machine. Multiply by days between scheduled deliveries and add a 20% buffer. Storing fuel on construction sites also means preparing for weather delays or vendor disruptions. Install containment basins sized at 110% of the tank volume. For larger sites, berms and double-walled tanks are recommended. Evaluate stormwater management and spill prevention measures. Choose fuel types that support sustainability goals, such as renewable diesel. Use historical data to fine-tune your site’s specific fuel needs over time.