Key Takeaways

- Fuel polishing and diesel tank polishing prevent shutdowns, corrosion and injector damage in stored fuel systems.

- Professional diesel fuel polishing restores off spec fuel, avoiding costly disposal and replacement.

- Coalescers, separators and filtration are essential to remove water, sludge and diesel bugs effectively.

- Portable and heavy duty systems let you polish fuel on site for fleets, marine users and generators.

- Choosing qualified providers for fuel polishing and polishing diesel fuel tanks ensures compliance, documentation and reliable uptime.

Table of Contents

Fuel Polishing

Fuel Polishing means circulating stored diesel through a dedicated multistage system. This process removes water sludge and fine solids more thoroughly than basic pump filtration. It answers the question what is fuel polishing in practical terms restoring fuel that would otherwise be considered unusable. Diesel fuel polishing and polishing diesel fuel are necessary when tanks remain unused for months when microbial growth occurs or when reliable starts are crucial for critical generators. By combining circulation separation and fine filtration fuel polishing ensures backup power marine vessels and fleets are always prepared.. It protects injectors, minimizes filter clogging, and supports compliance with guidance from Energy and EPA on clean storage. For high risk facilities, diesel tank polishing prevents shutdowns and protects sensitive medical or data systems.

What Is The Fuel Polishing Procedure?

A professional fuel polishing procedure begins with sampling and inspection. Technicians use a fuel polishing truck or portable rig to circulate fuel separate water capture sludge and filter contaminants to fine micron levels. This may involve polishing diesel fuel tanks by bottom sweeping. Final testing ensures fuel stability.

What Is Fuel Polishing On A Generator?

Fuel polishing on a generator keeps standby or prime power units supplied with ultra clean fuel. Systems continuously or periodically polish fuel in day tanks and bulk tanks. This prevents injector damage clogged filters and hard starts. For critical facilities diesel fuel polishing avoids costly outages during grid failure. Verification increases reliability.

Purify Fuel And Clean Your Storage Tanks To Prevent Unexpected Engine Shutdown

Contaminated diesel causes blocked filters injector wear and sudden shutdowns. Fuel polishing restores stored fuel quality. Tank cleaning removes sludge and microbial growth that polishing fuel alone cannot fix. Combining diesel tank polishing with structured cleaning prevents air locks power loss and costly emergency repairs. For generators marine vessels and fleets professional diesel polishing and periodic tank inspections are key to avoiding unplanned outages. Follow guidance from NFPA and SAE on storage standards, and partner with trusted fuel polish specialists who document results through clear before and after testing reports. This proactive approach extends injector life stabilizes combustion protects sensitive equipment and maximizes uptime for mission critical operations year round.

Worried Your Stored Diesel Will Fail When You Need It Most?

If your generators, fleets, or marine tanks sit for months, hidden water, sludge, and diesel bugs are already attacking injectors and filters. Our fuel polishing and tank cleaning checks contamination, restores fuel quality, and helps you avoid expensive emergency shutdowns and failed compliance inspections.

Advantages Of Fuel Polishing

Professional fuel polishing provides cleaner fuel leading to better combustion fewer breakdowns and longer engine and asset life. This process cuts premature filter and injector replacements lowering the total cost for operators. By restoring fuel polishing diesel fuel reduces waste supporting sustainability. Diesel fuel polishing and diesel tank polishing ensure compliance and protect critical backup power operations. You can partner with us to implement scheduled fuel polishing programs. These programs improve reliability protect warranties and keep gas & diesel fuel polishing under tight technical control. Clear reporting and fuel sampling records help maintenance teams justify budgets and demonstrate responsible risk management continuously.

Key Qualities To Look For In A Fuel Polishing Service

These are the key qualities to look out for when considering a fuel polishing service;

- Certified technicians with proven fuel polishing and diesel polishing experience plus references from generator, marine and fleet clients.

- Modern equipment including coalescers, magnetic conditioning, fine micron filters and safe fuel polishing truck or portable rigs.

- Clear scope, sampling, and reporting that verify fuel polishing system performance and final fuel cleanliness.

- Strong safety culture, waste handling compliance and adherence to EPA and local environmental rules.

- Rapid response times, transparent pricing, and documented guarantees that protect uptime on critical polishing diesel fuel tanks and storage sites.

- Ability to integrate fuel polish programs with existing maintenance schedules, remote monitoring and periodic fuel polishing reviews for long term reliability and risk reduction across facilities.

Seeing Sludge, Dark Fuel, Or Filter Clogs? Don’t Dump That Diesel Yet.

Before paying to dispose of “bad” fuel, have it professionally polished. Multi-stage separation and fine filtration can often restore off-spec diesel to usable condition, cutting waste and extending tank life while meeting EPA, NFPA, and ISO cleanliness expectations.

How Fuel Polishing Coalescer And Water Separator Systems Work

Coalescer and separator systems are essential for effective fuel polishing. As contaminated fuel circulates, coalescer elements cause tiny water droplets to merge into larger drops. Gravity then separates these larger drops. High efficiency filters retain solids and microbial debris. Clean fuel subsequently returns to the tank. This process protects injectors and prevents corrosion inside polishing diesel fuel tanks. Water accelerates diesel bugs, rust, and acid formation. Therefore, removing water through diesel fuel polishing significantly extends storage stability. Quality fuel polishing design adheres to best practices from SAE and similar organizations. This ensures that gas & diesel fuel polishing delivers repeatable and verifiable water control. Operators must routinely inspect elements, record differential pressure readings, and schedule replacements before restriction threatens system reliability. Maintaining top performance is crucial.

Portable Fuel Polishing Options For On-Site Use

Portable fuel polishing systems offer flexible cleaning for fuel tanks at marinas worksites and remote locations. These compact carts or skid units eliminate the need to move tanks. They combine pumps multi stage filters and water separators to polish fuel in various applications. These include marine craft RVs construction equipment and small generators. Capacity typically ranges from low to mid-range flows suitable for modest diesel tank polishing jobs. This setup allows operators to target polishing fuel where contamination exists. When choosing a unit verify hose length power supply micron rating and compatibility with diesel fuel polishing tasks. Proper sizing prevents long circulation times. Built in sampling ports aid quick field verification of successful fuel polishing outcomes.

Heavy Duty Portable Fuel Polishing Options For Large Tanks

Heavy duty portable fuel polishing systems support large industrial tanks bulk storage farms and marine bunkering operations. These rigs have high flow pumps robust hose sets and multi stage separators. They manage heavy sludge loads while polishing diesel fuel efficiently. Typical systems reach 15-50 gallons per minute or more. This makes diesel tank polishing viable without long downtime. Skid or trailer packages help service providers respond quickly. When specifying evaluate motor type duty cycle filter availability and what is fuel polishing system certification. Quality equipment ensures consistent results and a strong fuel polish service reputation.

How Businesses Can Integrate Fuel Polishing Services

- Assess existing customers with diesel storage, then propose fuel polishing as an add on to maintenance contracts.

- Invest in scalable diesel fuel polishing equipment, training and insurance, starting with portable units before expanding capacity.

- Partner with reputable suppliers who explain what is a fuel polisher, provide spares, and assist with system setup and compliance.

- Build simple service packages, for example annual diesel tank polishing and testing bundles for fleets and generators.

- Track outcomes with reports, photos and lab results to prove polishing fuel value and secure long term client relationships.

Use our turnkey starter kits, marketing materials and technical support to launch profitable fuel polishing services quickly and confidently in your market.

Managing Critical Power Sites? Lock In Documented Fuel Uptime.

Hospitals, data centers, and industrial sites cannot afford dirty fuel. We design scheduled diesel tank polishing programs with lab reports, before/after sampling, and standards-based procedures so you can prove reliability to auditors, insurers, and OEMs.

Electric, Pneumatic, And Automated Fuel Polishing Systems Compared

| System type | Key features | Best use cases |

|---|---|---|

| Electric fuel polishing | Plug in power, steady flow, simple control panels, moderate investment | Workshops, depots, routine polishing diesel fuel on medium storage tanks reliably |

| Pneumatic fuel polishing | Air driven motors, intrinsic safety where vapors exist | Hazardous sites needing compliant diesel fuel polishing and fuel polishing support |

| Automated systems | Timers, sensors, remote alerts, continuous fuel polishing cycles, detailed logs | Critical generators and high value storage needing constant verified protection |

| Hybrid designs | Combine features for tailored fuel polish configurations | Contractors standardizing gas & diesel fuel polishing across locations efficiently with simplified training and documentation |

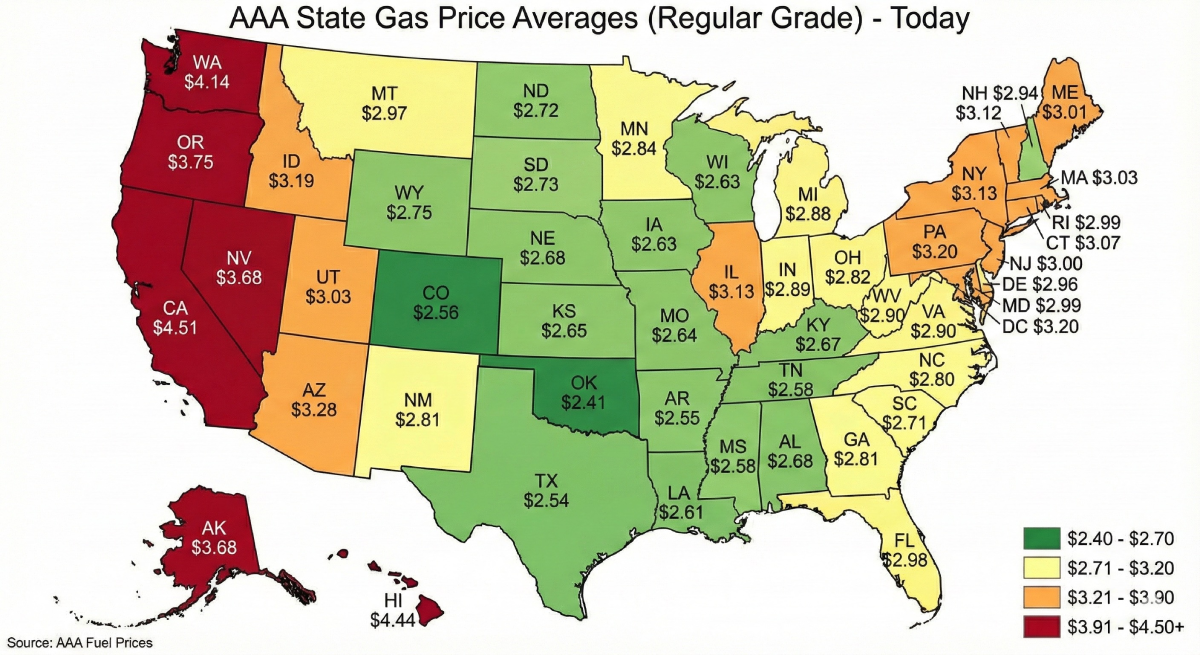

How Much Does Fuel Polishing Cost?

Fuel polishing costs vary based on tank size, contamination level, accessibility, and travel requirements. Many service providers calculate prices per gallon. They often have minimum rates for small diesel tank polishing jobs. Other companies prefer flat project fees or hourly charges. Fuel with heavy contamination needing multiple passes or biocide treatment will cost more than light polishing fuel maintenance. Transparent quotes should clearly itemize sampling, fuel polish equipment use, disposal handling, and verification tests. Comparing offers helps you assess the true value of what is fuel polishing. Choose providers who explain inclusions clearly and follow industry standards from API and EPA. This approach ensures reliable diesel fuel polishing results and protects engines globally.

What Contaminants Does Fuel Polishing Remove?

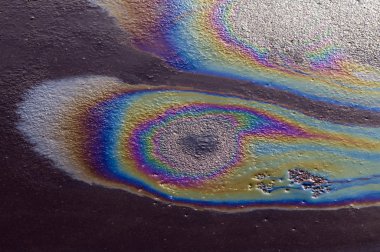

Effective fuel polishing removes water sludge rust microbial colonies and suspended solids. These contaminants damage engines and storage systems. Water causes corrosion and injector damage promoting diesel bugs. Particulates and sludge restrict fuel flow and clog filters potentially causing sudden shutdown. Multi stage separation and filtration reliably eliminate these issues.This process restores clear reliable fuel. Diesel fuel polishing also cleans tanks of biomass making biocide dosing much more effective. Regular analysis, guided by standards like ISO 4406, confirms cleanliness levels and proves fuel polish programs keep contamination under control for critical applications. Consistent monitoring and documentation build trust with auditors, equipment manufacturers and stakeholders who depend on resilient, compliant fuel polishing strategies.

What Are Diesel Bugs And How Are They Treated With Fuel Polishing?

Diesel bugs are microbial colonies thriving at the fuel water interface. They consume hydrocarbons creating acids sludge and corrosive deposits. Fuel polishing removes water and biomass. Compatible biocides kill remaining organisms. Together, diesel fuel polishing and chemical treatment prevent regrowth. This protects polishing diesel fuel tanks and supports cleaner combustion in marine generator and fleet applications.

Can Fuel Polishing Prevent Corrosion And Carbon Build-Up?

Removing water sludge and particles via fuel polishing reduces internal corrosion in tanks lines and injectors. Cleaner fuel enables more complete combustion which minimizes soot deposits and carbon buildup on injector tips and valves. This process combined with periodic diesel tank polishing prolongs component life and stabilizes performance.

How Often Should Fuel Be Polished?

The necessary frequency for fuel maintenance depends on turnover environmental conditions and asset importance. Stored diesel for backup generators requires fuel polishing assessments at least annually. Areas that are humid or high risk need more frequent checks. High consumption fleets should incorporate diesel fuel polishing when testing indicates contamination. Long term storage marine bunkers and hospitals commonly implement scheduled diesel tank polishing and polishing fuel programs. Always follow guidance from manufacturers and standards bodies. Use sampling to determine the necessity to polish fuel. Proactive scheduling prevents expensive reactive repairs and ensures regulatory compliance for gas and diesel fuel polishing operations. Align inspection records with all regulatory and insurance requirements.

What Are Some Problems That Can Occur During Fuel Polishing?

Effective fuel polishing requires vigilance against common problems. These include rapid filter plugging leaks from poor hose connections or disturbing heavy sludge without complete removal. Incorrect pump sizing or bypassing return lines can damage tanks or leave pockets of dirty fuel. Using incompatible additives ignoring ventilation or mishandling waste risks breaching environmental regulations. Underpowered systems may not achieve proper diesel fuel polishing results on large tanks.

To prevent these issues select trained technicians and verify what is fuel polishing system specifications. Insist on fuel sampling both before and after the service. Clear procedures proper grounding safety checks and strong supervision protect both equipment and workers. Document all incidents correct root causes quickly and refine fuel polishing plans. This approach ensures every project delivers reliable repeatable cleanliness outcomes across all serviced tanks consistently.

Is It Possible To Polish Gasoline?

Yes, but fuel polishing for gasoline is more limited. Gasoline has higher volatility and different stability challenges, so systems must be specifically rated. Some providers polish fuel in gasoline tanks using filtration and water separation, but compatibility, vapor control and safety requirements are critical. Diesel oriented fuel polishing rigs are not always suitable. For mixed facilities, dedicated gas & diesel fuel polishing strategies prevent cross contamination. Always confirm fuel polishing recommendations with manufacturers and follow guidance from NFPA for flammable liquids. When uncertain, consult specialists before attempting gasoline polishing fuel operations. Prioritizing correct design avoids ignition risks, equipment damage and ineffective treatment when handling sensitive gasoline inventories alongside traditional diesel fuel polishing work.

Building A DIY Fuel Polishing System At 15 GPM

Some operators attempt DIY fuel polishing systems using pumps housings and filters typically sized for 15 gallons per minute. While possible, design errors can harm tanks or leave contaminants behind. A correct understanding of what is a fuel polisher is essential. A reliable system requires water separation fine filtration safe hoses grounding and proper power sources. Comparing costs often reveals that commercial diesel fuel polishing kits offer better reliability and certification than DIY builds. If pursuing DIY polishing fuel follow credible manufacturer guides. Never bypass safety and always validate results with sampling to confirm effective fuel polish performance. Expert consultation before building reduces risk supports compliance and ensures your fuel polishing project genuinely protects engines instead of introducing new hazards.