Key Takeaways

- HVO diesel is basically a synthetic diesel made from stuff like hydrotreated vegetable oil and old waste fats. It’s a great diesel alternative.

- A lot of modern engines can use HVO 100 diesel without needing any modifications

- When you compare HVO vs diesel, the HVO fuel is much better for the planet, offering lower carbondioxide and cleaner exhaust fumes.

- If you compare HVO vs biodiesel, HVO biofuel wins for practical reasons: it stores better and performs better in cold weather.

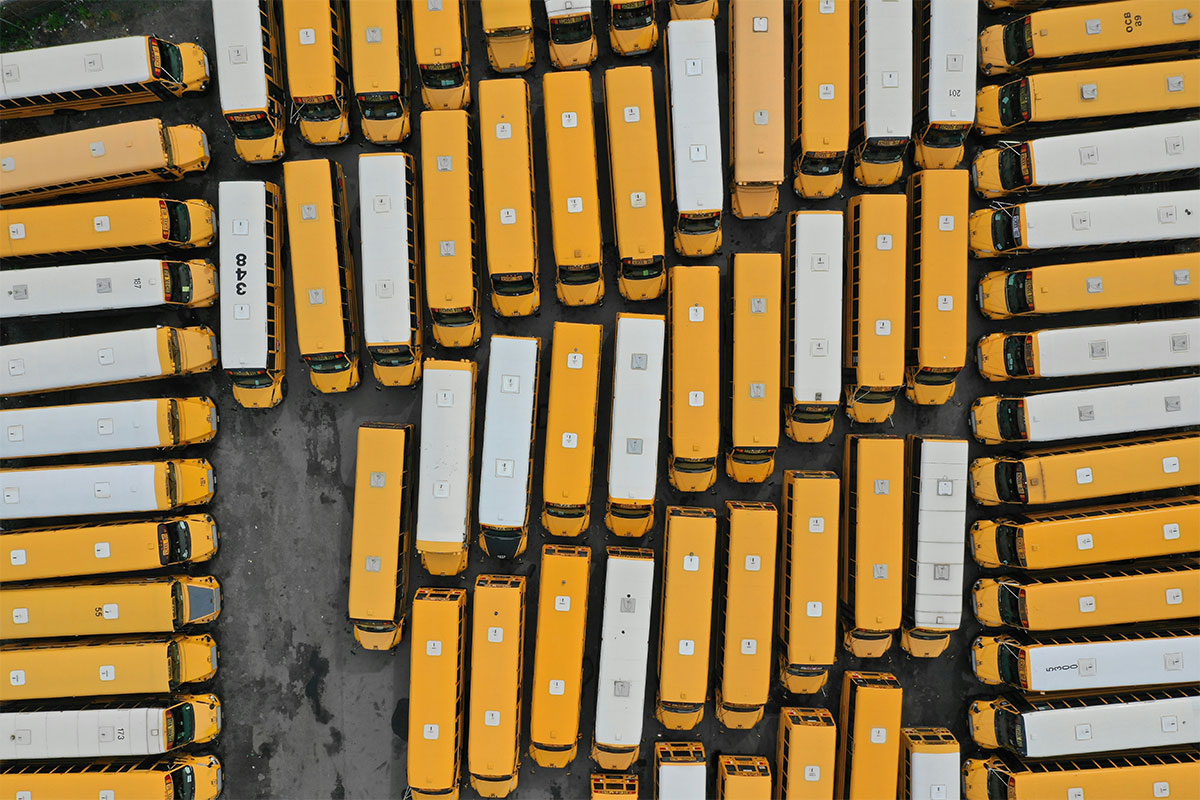

- Businesses can easily switch to HVO renewable diesel to reduce their emissions while still using their current fleet of vehicles.

Table of Contents

HVO Diesel

HVO diesel is a synthetic paraffinic fuel made from renewable feedstocks. It performs like high-quality fossil diesel but is a premium alternative with very low sulfur and aromatics, burning cleanly. HVO is created by treating oil or fat with hydrogen, forming stable hydrocarbon chains that behave like diesel. Unlike FAME biodiesel, this chemistry allows for long storage with less oxidation. Businesses switching to HVO renewable diesel can enhance sustainability, potentially reducing operating costs through lower maintenance and reliable cold-weather starts.

What Is HVO?

HVO, or Hydrotreated Vegetable Oil, is a synthetic renewable biofuel made from feedstocks like used cooking oil and animal fats. This HVO fuel can be used as HVO 100 or blended with regular diesel. Practically, HVO supports decarbonisation in heavy transport, construction, marine, and backup power. It offers deep lifecycle carbondioxide cuts and similar energy content to conventional diesel. Companies adopt HVO to meet sustainability goals without immediately switching to electric or hydrogen vehicles. Due to its environmental and performance benefits, demand for HVO is increasing in road freight, municipal fleets, and industrial applications.

Thinking About Switching Your Fleet To HVO Diesel?

HVO renewable diesel lets you cut lifecycle CO2 by up to 90% while still using your existing engines and tanks. Learn how HVO 100 fits trucks, off road machines and backup generators without major hardware changes.

Is HVO Compatible With Modern Diesel Engines?

Hydrotreated Vegetable Oil (HVO) diesel is often drop in compatible with existing diesel infrastructure. Original Equipment Manufacturer approvals are increasing, and many modern vehicles can use pure HVO 100 or HVO blends without requiring hardware modifications. While operators must still confirm compatibility for specific engines, the overall trend is favorable.

- Commercial Vehicles: A wide range of truck and bus manufacturers now list HVO diesel fuel as an approved alternative diesel fuel.

- Off-Road and Construction: Several engines in the off-road and construction sectors consider HVO renewable diesel a valid diesel alternative, typically with similar service intervals.

- Passenger Cars:Some car manufacturers permit the use of HVO 100 diesel, provided the local fuel quality meets their specifications.

- Engine Control: Engine control systems generally treat biodiesel-HVO blends similarly to standard diesel due to their close viscosity and density characteristics.

- Fuel Housekeeping: Even when using high-grade HVO diesel, maintaining good fuel housekeeping practices remains essential.

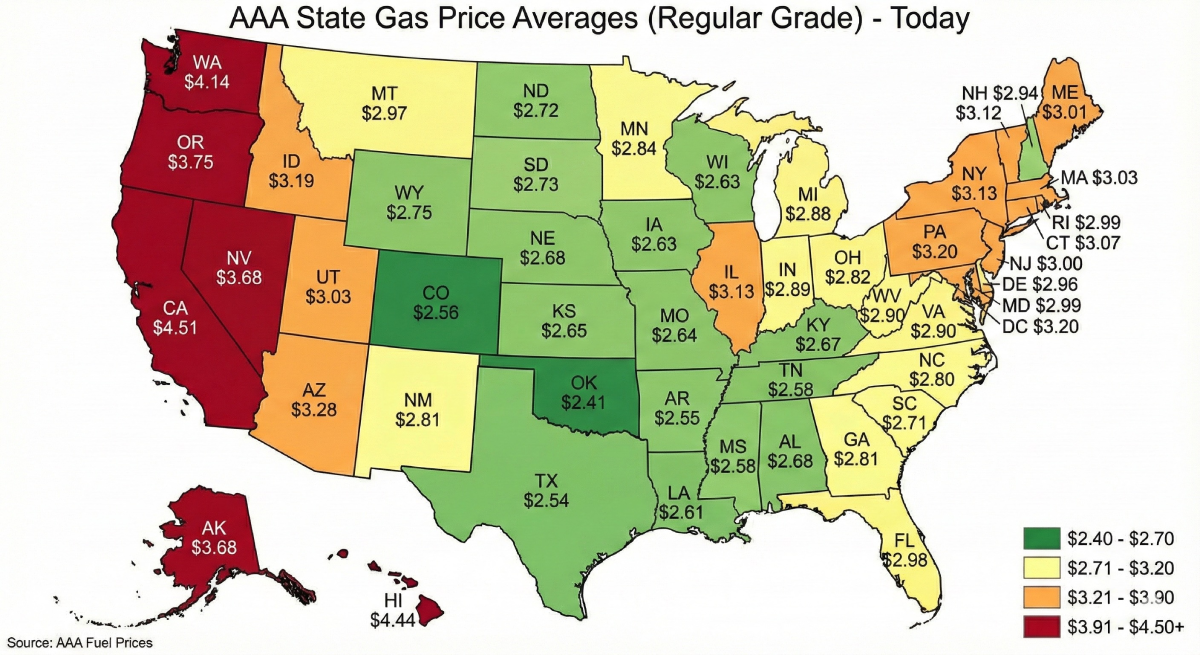

HVO Vs. Diesel

Operators compare HVO to diesel for performance and cost. Both deliver similar energy and efficiently power compression ignition engines. Key differences lie in origin, emissions, and handling. HVO is made from hydrotreated vegetable oil and waste fats, whereas standard diesel is crude oil-derived. The table below summarises key points in a simple way.

| Factor | HVO Diesel | Conventional Diesel |

|---|---|---|

| Origin | Renewable hydrotreated vegetable oil and fats | Fossil crude oil |

| CO2 lifecycle | Up to around 90% lower | Baseline reference fuel |

| Storage stability | Very good for synthetic HVO fuels | Good but can oxidise over long periods |

| Typical use | Fleets seeking diesel fuel alternatives | General road and off road users |

Unsure Whether HVO Beats Standard Diesel Or Biodiesel?

From cold flow performance to storage stability and DPF health, HVO diesel behaves differently from both conventional diesel and FAME biodiesel. See side by side comparisons to decide which fuel really works best for your vehicles and standby equipment.

HVO Vs. Biodiesel

When comparing HVO vs biodiesel, remember the chemical and real world differences. Traditional FAME biodiesel is made by transesterification. HVO stands for hydrotreated vegetable oil, creating a paraffinic fuel. The structural difference HVO and biodiesel explains why HVO often performs better. Advantages of HVO biodiesel over FAME include better cold flow and stability. Some people use terms like HVO FAME or biodiesel HVO to distinguish them. While the HVO biodiesel price might be higher, buyers often accept it for better storage and engine reliability.

Can I Put an HVO Diesel In My Car?

The primary question for many drivers is whether they can use HVO diesel at the pump. While many modern diesel vehicles are technically compatible with HVO 100 or its blends, it is essential to comply with all legal and warranty requirements. Drivers must always consult their vehicle’s handbook and check the filler cap for specific labels such as HVO 100, HVO100 diesel, or HVO 100 fuel. When a vehicle is approved for its use, this fuel generally serves as a direct diesel alternative.

Common questions revolve around can you mix biodiesel and diesel, can I use biodiesel in my diesel car, and can you put biodiesel in a diesel engine. Most manufacturers permit modest blends, but they impose limits on higher concentrations. If you are uncertain, particularly before using high-percentage blends or combining HVO biodiesel with fossil diesel, it is best to consult with a dealer.

Is HVO Better For DPF?

HVO diesel fuel generally benefits diesel particulate filters (DPF). Its cleaner burn reduces soot, leading to fewer regenerations and lower back pressure. Fleet operators often observe cleaner oil and stable back pressure readings. While HVO eases the burden on the DPF system, proper driving and servicing remain necessary. Reported issues with HVO are usually due to poor tank hygiene or fuel contamination, not the fuel’s properties.

What Are The Benefits Of Using HVO Fuel?

The main HVO fuel benefits combine environmental and operational gains. Users typically value the following points.

- Significant lifecycle carbondioxide reduction when using HVO renewable diesel instead of fossil fuel.

- Cleaner combustion for HVO fuel with low sulfur and aromatics which helps local air quality.

- Strong cold flow performance compared with many biodiesel blends in winter.

- Good storage stability for HVO biofuel which supports backup generators and standby plants.

- Broad compatibility with modern engines seeking a high quality alternative diesel fuel.

For fleets that adopt HVO 100 diesel or blends, these benefits can support corporate environmental targets without needing to change their vehicles.

Up To 90% CO2 Reduction With HVO Fuel

Marketing materials often claim HVO 100 or HVO 100 fuel can cut carbondioxide by up to 90% versus standard diesel. This high figure reflects “well-to-wheel” or lifecycle emissions, covering collection, processing, transport, and combustion, not just tailpipe gases. Waste based feedstocks, like used cooking oil for bio HVO diesel, generally yield greater savings than crop-based fuel. Comparisons must use consistent lifecycle boundaries. Carefully sourced fossil-free diesel like HVO 100 fuel can significantly reduce fleet carbon footprints.

Is HVO Renewable Diesel A Sustainable Fuel?

(HVO Diesel liquid on white background)

The sustainability of HVO (hydrotreated vegetable oil) renewable diesel relies on feedstock and production. Using waste oils and residues yields significant greenhouse gas savings with minimal land use change. Major brands like Lubiq and HVO Green D+ emphasize traceable supply chains and certification. In Europe and the UK, HVO suppliers must meet renewable fuel standards and trace inputs. Some markets use various terms like HVO kraftstoff in Germany, HVO oil, or premium HVO diesel. Buyers should request documentation detailing origin, carbon intensity, and sustainability compliance. HVO biofuel is crucial for transitioning heavy transport, marine operations, and backup power where electrification is not yet feasible.

Need Help Finding Certified HVO Fuel Suppliers?

Supply, sustainability certificates and price per litre can vary widely between HVO providers. Get guidance on sourcing waste based HVO, checking documentation and arranging bulk deliveries to your depot or site tanks.

What Raw Materials Are Used To Make HVO?

HVO diesel is mainly produced from waste streams like used cooking oil, processed animal fats, and vegetable oil residues. These feedstocks are cleaned and converted into hydrotreated vegetable oil (HVO) using high-pressure reactors. To ensure sustainability, certification systems restrict high-risk crops. Buyers should prioritize suppliers using genuine waste streams and minimizing palm oil. This improves the HVO’s sustainability and strengthens its claim as a credible diesel alternative.

What Is The HVO Production Process?

The production of Hydrotreated Vegetable Oil (HVO) diesel involves a multi-step refining process. Initially, the feedstock is filtered and pretreated to eliminate water and impurities. It then proceeds to a reactor where hydrogen is introduced under pressure. This critical step, known as hydrogenation, yields stable paraffinic molecules, which constitute the HVO. Following hydrogenation, the fuel undergoes further purification, fractionation, and blending to ensure it meets specific performance criteria, such as the required cetane number and cold flow properties. The final product is high-quality HVO100 diesel or various blends that perform similarly to conventional diesel in engines. A key advantage is the exceptional stability of the molecules, which grants the fuel resistance to oxidation. This makes HVO diesel an excellent choice for backup generators or for seasonal operations requiring stored fuel.

How Is HVO Made At Neste?

Neste is one of the best known producers of HVO renewable diesel. The company processes waste oils and fats into HVO 100 products at large scale plants, serving road, marine and aviation users. Their proprietary technology focuses on efficient hydrogen use, heat recovery and strict quality control. In this type of facility the goal is consistent HVO diesel quality across batches so that fleet operators can rely on predictable performance. The fuel ships as HVO100 diesel, blends or specialist brands tailored to climate and application. It demonstrates how innovation in hydrotreated vegetable oil processing can deliver clean burning HVO fuels at industrial scale.

What Are The Downsides Of HVO Diesel?

Despite its benefits, HVO diesel has drawbacks, primarily its higher price compared to fossil diesel, driven by feedstock and processing costs, with premium “fossil-free” products costing even more. Supply can be limited, requiring fleets to plan logistics around reliable suppliers like Lubiq. Misconceptions about HVO issues often stem from mixing it with degraded fuel or poor tank maintenance. Technically, while storage is generally good, poor housekeeping can still cause water, corrosion, and microbial growth, risks common to many diesel alternatives, underscoring the need for regular tank checks and polishing.

Does HVO Go Off Or Get Diesel Bug?

HVO diesel boasts superior oxidation stability compared to FAME biodiesel, extending its usable life in storage, which benefits standby or seasonal equipment. However, like all diesel, microbial contamination (diesel bug) remains a risk if water accumulates in tanks. Regular checks, water drainage, tank cleaning, and biocide treatments are still necessary. Given that renewable HVO diesel lacks FAME, it degrades less quickly. Nonetheless, general good storage practices for mineral diesel and gasoline must still be followed for this fuel alternative.

How Much Does HVO Diesel Cost Per Litre?

The price of HVO diesel per litre varies by region, feedstock, and policy, often costing more than standard road diesel. UK buyers frequently search for “HVO fuel price per litre uk.” The final price is influenced by wholesale/retail margins and taxation. Feedstock scarcity and processing costs shape the HVO biodiesel price, although climate policies can narrow the cost gap with fossil fuels, especially for professional fleets. Fleets must evaluate the total cost of ownership, considering savings from cleaner combustion, reduced maintenance, branding, and any credits for using diesel fuel alternatives, as a simple pump price comparison is insufficient.

Where To Buy HVO Fuel Near You?

HVO fuel can be sourced from local distributors, oil companies, and independent depots through bulk delivery to UK and other customers. Some truck stops and public stations also offer dedicated HVO 100 pumps.

Online searches like “where can I buy HVO fuel” often lead to supplier maps. In German-speaking markets, it’s known as HVO Kraftstoff. Specialist traders like Lubiq also connect buyers to certified product. Industrial users often receive contract deliveries to on-site tanks for all-fuel engine generators or mixed fleets using various diesel alternatives. Our team can connect you with certified regional suppliers for HVO or other diesel alternatives.