Key Takeaways

- Renewable diesel is a drop-in diesel-type fuel made from renewable feedstocks

- Renewable diesel vs diesel comparisons matter for engines, emissions, and fuel handling

- Is diesel fuel renewable is usually answered no for fossil diesel, yes for the renewable alternative

- Can I use renewable diesel is often yes, but always follow manufacturer guidance and warranties

- Costs vary by region, policy, and supply, not only by production cost

Table of Contents

What Is Renewable Diesel?

Renewable diesel is a liquid transportation fuel. It is produced from renewable raw materials and meets all standard diesel fuel specifications. Simply put, this diesel range fuel comes from fats, oils, and similar feedstocks instead of crude oil. Many people ask what is renewable diesel is because it differs significantly from biodiesel, even if both use similar inputs. The key difference is that renewable diesel fuel is refined so its molecular structure is nearly identical to that of fossil diesel. This allows it to work as a direct replacement for fossil diesel in most engines. Unlike fossil diesel, which uses ancient carbon from crude oil, renewable diesel uses modern carbon sources like recent plant growth or waste oils, making it a renewable product.

What Is Renewable Diesel Commonly Called?

Renewable diesel is known by several names in the industry. Suppliers and regulators commonly refer to it as hydrotreated vegetable oil, often shortened to HVO. Other terms include paraffinic diesel or a renewable hydrocarbon diesel. In general conversation, it may be categorized under renewable diesel fuels with other lower-carbon alternatives, even when the chemical compositions differ.

Naming conventions vary by region. Some markets use HVO as the primary label. Others prefer the phrase renewable diesel fuel because it indicates a direct drop-in replacement for fossil diesel. You may also encounter the term sustainable diesel fuel in marketing, but because definitions vary, always verify technical specifications. If a document uses renewable diesel/fuel, it is usually a shorthand for renewable diesel products in diesel applications. Always confirm the fuel meets regional diesel standards for your equipment.

How Is Renewable Diesel Different From Diesel #2?

This comparison is important because most on-road and off-road diesel users purchase fuel based on familiar grades, such as diesel number two. When people compare diesel #2 vs renewable diesel, they want to know about potential changes in performance, storage, and compatibility. It also matters for fleets managing warranties, fuel quality programs, and cold weather planning. The biggest confusion is that both fuels are usable in similar engines, yet their origins and processing differ. Comparing renewable diesel vs diesel 2 involves more than just the feedstock. It is about how the fuel is processed and the final molecular structure. Below is a practical table for renewable diesel vs regular diesel comparisons, using typical characteristics. Exact values vary by producer and region, so treat it as a general guide.

| Feature | Diesel number two | Renewable diesel |

|---|---|---|

| Primary source | Crude oil refining | Renewable fats and oils and wastes |

| Chemistry type | Petroleum diesel mix | Hydrocarbon diesel like fuel |

| Sulfur level | Varies by regulation | Often very low, depends on supply |

| Cold flow | Seasonal blends used | Can be good, depends on treatment |

| Engine use | Standard diesel engines | Often drop in for diesel engines |

| Emissions profile | Higher lifecycle carbon | Lower lifecycle carbon potential |

Can Your Truck Run Renewable Diesel Without Any Mods?

Renewable diesel is often a “drop-in” fuel, but smart owners still verify specs, warranties, and supplier documentation before switching. Get a quick compatibility checklist you can use before your next fill-up or fleet pilot.

Is Diesel Considered Renewable Or Nonrenewable?

Standard fossil diesel is generally classified as nonrenewable because it is produced from crude oil, which forms over very long time periods. Therefore, questions like is diesel renewable and is diesel fuel renewable usually have a simple answer for conventional diesel, which is no.

The classifications of renewable and nonrenewable concern the energy source and whether it can be replenished on human time scales. Fossil diesel is derived from fossil carbon and does not replenish quickly, placing it in the nonrenewable category. When people ask whether diesel fuel is renewable or nonrenewable, the confusion often stems from the fact that diesel engines can operate on multiple fuel types. The engine itself does not determine if the fuel is renewable; the feedstock and production pathway make that decision. In contrast, renewable diesel is generally considered renewable because its inputs are renewable feedstocks and the production process is specifically designed to create a diesel-like product from those inputs.

Can Renewable Diesel Be Used In Existing Engines And Vehicles?

Growing interest in renewable diesel is driven partly by its compatibility. It often functions as a drop-in fuel, directly replacing fossil diesel without requiring engine modifications. This answers the common question, “can I use renewable diesel without buying a new vehicle?” For many fleets, this is practically true, but verifying warranties and manufacturer statements is the responsible approach.

Adoption is eased because renewable diesel can usually utilise existing fueling infrastructure, including tanks, dispensers, and delivery vehicles. However, sites must still manage fuel quality. Proper storage, water control, and cleanliness remain crucial for any diesel supply. Infrastructure readiness also depends on local supply. When evaluating renewable diesel fuels, fleets should confirm a consistent supply before a large-scale transition.

Confused By Diesel #2 Vs Renewable Diesel Labels?

Diesel #2 and renewable diesel can look similar at the pump, but their source, processing, and lifecycle emissions story are very different. Use a simple side-by-side comparison guide to decide what matters most for your engine, storage, and cold-weather planning.

Can I Use Renewable Diesel In My Diesel Truck?

For many modern diesel trucks, “can I use renewable diesel” is a reasonable question because owners worry about injectors, seals, and emissions systems. Many fleets have successfully used renewable diesel with minimal changes, but owners must follow manufacturer guidance. Some manufacturers provide clear statements on allowable blends or full replacement use. Confirming the fuel meets required diesel specifications and having supplier documentation is critical for warranty terms when using renewable diesel fuel.

Real-world fleet usage often starts with pilot testing. Fleets may begin with a portion of vehicles, monitor filters and fuel economy, and then scale up. This approach helps validate performance for your duty cycle, climate, and maintenance schedule.

What Are The Downsides And Disadvantages Of Renewable Diesel?

Renewable diesel offers clear advantages, but its adoption is not yet universal. Limitations exist concerning supply, feedstock availability, and reliance on policy. It is also challenging for buyers to accurately assess claims, especially when the term sustainable diesel fuel is used loosely. Below are some reasons why adoption is not universal;

- Supply can be limited in some regions, which affects consistency for fleets.

- Feedstock availability can constrain growth, particularly if demand increases rapidly.

- Sustainability depends heavily on feedstock sourcing; not all pathways are equally sustainable.

- Pricing can rely significantly on credits and incentives, which are subject to change.

- Some users face uncertainty regarding product warranties and necessary documentation.

- Distribution and retail access often lag behind supply for fleets and terminals.

Scalability is a frequent challenge. Competition across many sectors for the same oils and fats can tighten markets. This may increase costs and raise concerns about indirect impacts, such as pressures on land use. These issues do not invalidate renewable diesel as an option. However, buyers must evaluate supply chains, certification, and program rules, not just tailpipe performance.

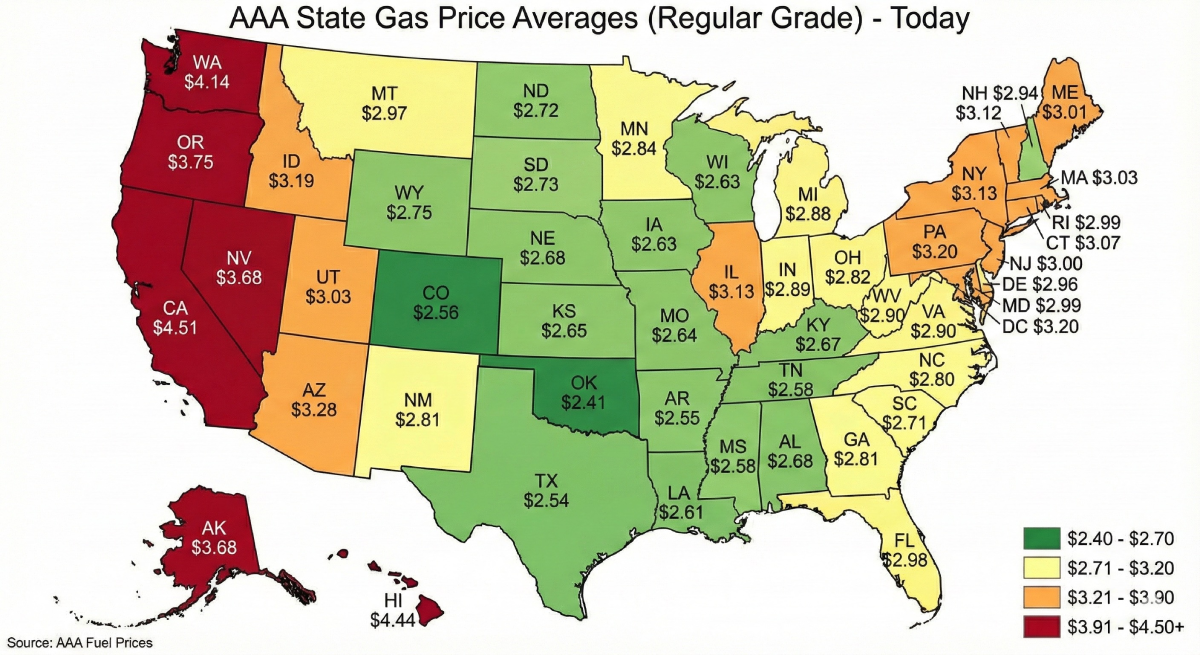

Is Renewable Diesel Cheaper Than Diesel?

The cost of renewable diesel varies based on location, supply method, and applicable credits. In some regions, its price is comparable to fossil diesel. However, in other areas, it can be significantly higher. This explains why renewable diesel vs diesel cost comparisons yield different results across regions and timeframes. Pricing also depends on the structure of fuel sales. Retail prices differ from bulk contracts.

Fleets often negotiate supply tied to terminals and credit values. Some purchasers evaluate the total cost of ownership, including emissions targets, while others focus only on the pump price. Regional price differences occur because supply and policy incentives are not uniformly distributed. Where supply is limited or credits are few, renewable diesel fuel costs more. Where policy support is strong and supply chains are established, pricing is more competitive.

Why Is Renewable Diesel Only Cost Competitive In California?

California is a key market for renewable diesel due to clean fuel credit systems that improve its economics. Programs like the Low Carbon Fuel Standard generate credits based on a fuel’s carbon intensity. These credits make lower-carbon fuels more appealing to both suppliers and buyers. Consequently, California sees strong adoption and competitive pricing for renewable diesel vs diesel compared to other regions. State-level incentives influence product distribution. Markets that highly reward low-carbon fuels attract more supply. Where such incentives are absent, renewable diesel vs diesel pricing differences may be larger, especially when production costs exceed those of fossil diesel.

How Is Renewable Diesel Made And Processed?

Renewable diesel is produced by processing renewable feedstocks to create hydrocarbon fuel molecules, which are similar to those in petroleum diesel. This method differs from biodiesel production, which uses a chemical conversion that leaves oxygen in the fuel molecules. Consequently, renewable diesel closely resembles conventional diesel in both storage and combustion characteristics.

The production process is essentially refinery-style upgrading. First, the feedstocks are cleaned and prepared. They are then processed under specific conditions to remove oxygen and restructure the molecules into the desired diesel range hydrocarbons. This explains the fundamentals, including the materials used and the core processing step.

What Feedstocks Are Used To Make Renewable Diesel?

Common feedstocks for renewable fuels include plant-based oils, such as soybean oil and canola oil, animal fats, and recycled oils like used cooking oil. These inputs significantly impact carbon intensity, availability, and public acceptance. Sustainability efforts focus on traceability and indirect impacts. While waste and residue feedstocks offer strong sustainability arguments, their supply is limited. Crop-based oils are more scalable but raise concerns based on production methods. When evaluating renewable diesel fuels, verify feedstock sourcing claims and program certifications.

What Is The Hydrotreating Process Used In Production?

Hydrotreating is a high-temperature, high-pressure process using hydrogen to remove oxygen from feedstock, converting it into hydrocarbon fuel. This process upgrades fats and oils into molecules that behave like fossil diesel. Consequently, renewable diesel is a hydrocarbon diesel replacement. Refinery-style operations are common because of the equipment and expertise overlap with petroleum refining. Removing oxygen creates a fuel with good stability and compatibility. This explains why renewable diesel differs from biodiesel in chemical makeup and performance.

What Are The Environmental And Performance Benefits Of Renewable Diesel?

Environmental benefits are assessed through lifecycle analysis, covering emissions from production, processing, transport, and use. Renewable diesel pathways, especially those using waste feedstocks, significantly reduce lifecycle greenhouse gas emissions compared to fossil diesel. Air quality can also improve depending on the engine, duty cycle, and local conditions. Fleets value performance benefits like reliability and low maintenance. Renewable diesel supports normal diesel engine operation without major modifications, qualifying it as one of the renewable fuels for diesel engines. The benefits are;

- Potential lifecycle emissions reductions compared with fossil diesel

- Potential reductions in some local pollutants depending on conditions

- Drop in use in many diesel engines which supports operational continuity

- Good fuel stability for storage and distribution when quality is managed

- Supports decarbonization targets without immediate fleet replacement

Trying To Figure Out If Renewable Diesel Is Worth The Price?

Renewable diesel pricing changes by region, supply access, and credit programs—not just production cost. Use a quick cost-check framework (retail vs bulk, supply stability, and policy-driven credits) to estimate what you’d actually pay where you operate.

How Renewable Fuel Obligations Affect Diesel Markets

Renewable fuel obligations aim to increase the use of renewable fuels and reduce lifecycle emissions in the fuel supply. Policies differ by region, but they typically establish compliance targets for obligated parties. These targets influence which fuels are produced, imported, and marketed.

Compliance involves mechanisms like credits, which are generated when renewable fuels are supplied. These credits can be traded or used to meet obligations. This activity impacts pricing signals and supply flows. For example, if credits are valuable, suppliers may increase deliveries of renewable diesel into that market. If credit values drop, supply incentives weaken. The market impact includes changes in blending strategies, new capacity investment, and shifting fuel availability. Consequently, buyers may find renewable diesel more available in certain regions, and prices will fluctuate with policy driven credit markets.

What RTFO Feedstock Information Requires

Renewable fuel standards like RTFO often require traceability and sustainability reporting for feedstocks. This ensures fuels meet sustainability standards and validates claims of greenhouse gas savings. Requirements typically involve documenting the feedstock’s origin, material type, and the supply chain process.

Sustainability verification relies on audits, certificates, and mass balance accounting based on the program. Reporting also includes greenhouse gas calculations using approved methods. For suppliers of renewable diesel, these regulations influence feedstock preferences and supply chain design. Buyers benefit because reliable documentation supports corporate reporting, emissions accounting, and procurement standards. If you buy renewable diesel fuel for a fleet that tracks emissions, you need supplier documentation that matches your reporting framework.