Key Takeaways

- Understand types of storage tanks from design, material and usage

- Ensure you’re compliant with safety regulations to minimise risks

- Make informed decisions that will help expand the duration of storage tanks

- Understand industry standards and why they are important

- Make informed decisions on which types of storage tanks are more appropriate for what kind of substances

Table of Contents

Types Of Storage Tanks

Storage tanks are containers usually used to hold liquids and gases. They’re generally used in various sectors like industrial, fuel and water storage. Storage tank classifications are categorized into several types according to design, material, industry application and location.

It’s important to choose the right type of storage tank for safety, maximizing storage capacity and being compliant. Our expert recommendations can help you achieve compliance, minimise risk and increase tank duration. In case you have any doubts or want to get help in figuring out how to get the best out of your tank, we will be more than happy to assist you.

Different Types Of Storage Tanks Explained By Design

The classification of storage tanks is based on their design and structural features. The most common types of storage tanks include;

Fixed Roof Tanks

These tanks are designed for liquids with low volatility. Their capacity ranges from thousands to millions of gallons, they have a permanent roof structure and are mostly used in the oil and chemical storage industries. They minimize air exposure, reduce contamination risk and ensure stability of liquids over time.

Floating Roof Tanks

They are designed to limit evaporation as they mostly contain highly volatile liquids. They comprise a floating roof mechanism that can either be internal or external. Floating roof tanks are mostly used in the petroleum industry. The floating roof design serves as a seal over the liquid it contains. The floating roof is always close to the liquid and preventsevaporation. As the volume of the liquid rises, the floating roof rises too, always maintaining a safe distance above the liquid to prevent evaporation.

Spherical Pressure Vessel

The tanks are most appropriate for storing high pressure gases such as liquified natural gas. Their spherical shapes assure the Gen stress distribution allowing them to sustain higher pressures. Where pressure control is crucial, the spherical pressure vessels are optimal

Not Sure Which Storage Tank Is Right for Your Industry?

From fuel and chemicals to water and gas, choosing the wrong tank can lead to leaks, fines, and safety risks. Our expert guide helps you match the right design and material to your application.

Industrial Tank Types By Material And Application

Storage tank classification can also be done based on the type of substances they contain and how they are used in industries. To optimize storage solutions, understanding the type of industrial storage tanks is important;

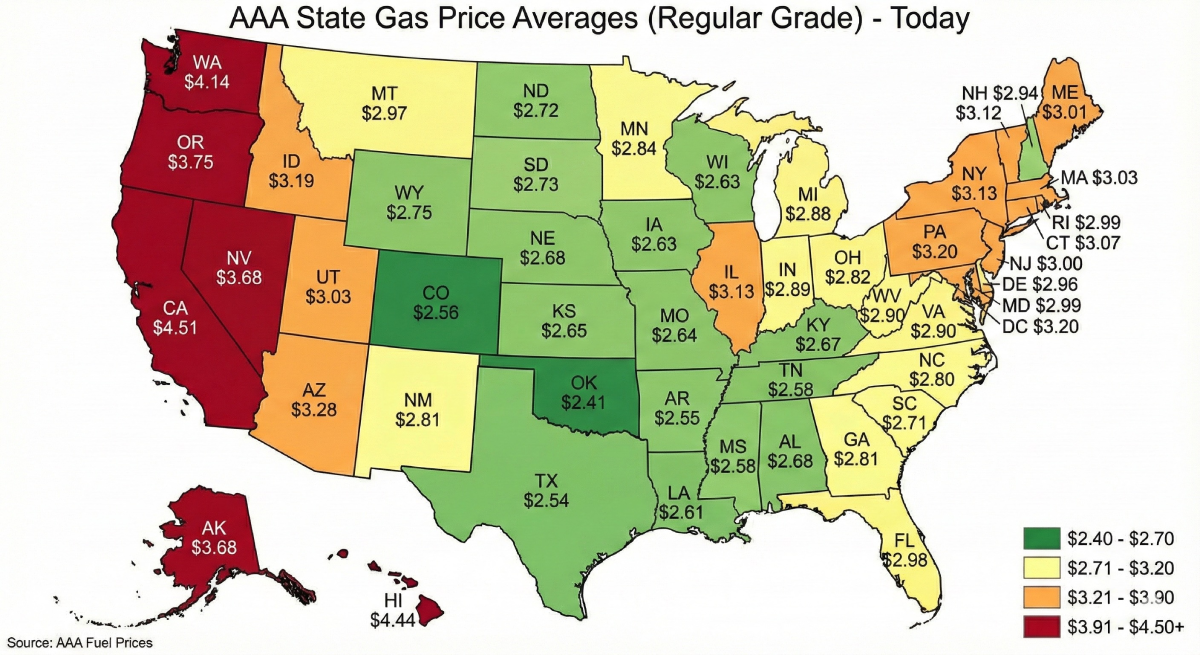

- Fuel tanks: These tanks require specific materials and design to be safe and compliant. They’re used to store gasoline, diesel and other fuels. They are typically made with material like steel or fiberglass, assisting that they last longer and resist corrosion. They can be aboveground or underground and may have some features like double walls and monitoring systems to make sure they’re safe for the environment.

- Oil tanks: They vary in structure and size depending on the volume and type of oil stored. They’re good for crude oil and petroleum products. Oil tanks have strict regulations especially concerning environmental protection. They must comprise measures for spill prevention, leak monitoring and be resistant to harsh environmental conditions.

- Gas tanks: Types of gas storage tanks have specialized features to handle the pressure of the substances they store which are usually high pressure gaseous substances. They are usually constructed with high strength materials that withstand pressures exerted by stored stages. They may also include safety features to relieve pressure and monitor leaks or pressure imbalances.

- Water tanks: Types of water storage tanks are important for both resident and commercial applications. They store water for drinking, cooking and other industrial processes.They are mostly designed with plastics, steel and concrete. They must adhere to strict safety standards and be cleaned regularly to avoid contamination and safety.

- Chemical Tanks: Types of chemical tanks are made to store industrial chemicals safely. They often require materials that can’t be corroded easily and resist different chemical reactions. They sometimes comprise safety measures such as leach detection, secondary containment and monitoring equipment to assure safety.

For operations to be streamlined and efficient, we can help you choose the right tank, be it for fuel, water or chemical storage. Reach us today and cut through the noise.

Aboveground And Underground Storage Tanks Explained

The placement of storage tanks can be the basis of their classification.

- Underground Storage Tanks (UST) – Due to their potential environmental risks, these tanks which are usually found at fuel stations are under very strict regulations and come with monitoring and leak detection systems which are required for them to be compliant. They are cost effective but require frequent maintenance to be ensure environmental safety

- Aboveground Storage Tanks (AST) – ASTS are easier to access given their aboveground location. They have varied uses for fuel, oils, chemicals and water storage. They permit visual inspections which enhance safety and ease compliance.

The regulations of both USTs and ASTs are different and subject to regulatory differences in different regions. The regulations mostly comprise guidelines on maintenance, installation, spill prevention and monitoring leaks. All these ensure environmental protection and compliance with regulations.

Need Help Navigating Storage Tank Regulations?

IBC, ASME, UST vs. AST—it’s a lot to take in. We’ll walk you through the compliance essentials, from spill prevention to pressure ratings, so you can avoid costly mistakes.

Specialized Storage Tanks For Unique Applications

Buffer tanks and expansion tanks are tanks that serve auxiliary purposes in some systems; like HVAC and mechanical systems, where they regulate pressure while ensuring safety.

- Buffer tanks – Buffer tanks are crucial in assuring consistency in performance for heating and cooling systems. They store excess fluid in a system as a reserve to be used when what is required is more than the available. Their role as buffers can boost system efficiency and reduce energy usage.

- Expansion tanks – Expansion tanks prevent pressure buildup caused by increasing fluid volume in changing temperatures. This expansion ability provides safety for systems that could be damaged by thermal expansion.

What Is The Difference Between An Expansion Tank And A Compression Tank?

Compression tanks and expansion tanks differed in application. Compression tanks used pressurized gas to maintain the pressure of a system, while expansion tanks are built to manage fluid expansions caused by temperature changes.

Pressure Tanks And High-Performance Storage Options

In some industries, there are processes that require pressure to be maintained at certain appropriate levels. Pressure tanks are designed to handle internal pressure and extreme conditions in order to keep pressure at the right levels in chemical processes, water treatment, oil and gas. They are important for maintaining safety and efficiency.

Pressure tanks are used in processes that require storage of liquids under pressure, so in selecting a pressure tank, you must consider the type of substance to be stored, the pressure rating and environment conditions. Only pressure tanks with the right material and design can ensure safety and reliability. Include vessels for gas, vapor, and liquid under pressure.

Maximize Safety and Lifespan with the Right Tank Setup

Underground or aboveground? Fixed roof or pressure vessel? Learn how tank type, orientation, and materials impact durability, maintenance, and legal safety.

Horizontal, Vertical, And Mobile Tank Designs Explained

Tank orientation and mobility have a great impact on performance and use:

- Horizontal tank: These are mostly used where space isn’t limited as they’re ideal for storing large volumes efficiently and require more ground space than other tanks

- Vertical tank: Appropriate for space saving and can be used for different substances

- Mobile tanks: These are temporary storage suitable for transporting substances. Not suitable for large scale stationary applications.

Every design type has its limitations that impact their application. For example, storage tanks are flexible, but cannot be used in long term storage and horizontal tanks carry large volumes but cannot be transported.

What Is The Difference Between A Storage Tank And A Storage Vessel?

It’s very common to hear words “tanks” and vessels used interchangeably, however, they have different uses in industry. For example, a storage vessel is a larger and more complex system while a storage tank is a simple container. If the differences are not understood, confusion may arise when it comes to complying with the different industry standards and regulations.

Tanks and vessels have different regulatory requirements. Especially when it comes to safety stat and compliance. So it is important for you to understand the terminologies, their classification, their usage and their regulatory context.

Standards And Regulations: IBC And ASME Tanks

The design and manufacturing of storage tanks is regulated by industrial standards such as IBC (Intermediate Bulk Containers) and ASME (American Society of Mechanical Engineers)

What Is An ASME Storage Tank?

For a tank to meet the ASME storage tank standard, it must adhere to specific code requirements for pressure vessels. They must undergo rigorous test and certification processes to be sure if structural integrity and safety requirements are met. For industries like oil, gas and chemical processing ASME standards are important to assure high safety standards and processes.

In the same light, IBC standards defined the means to safely transport and store various substances. Complying with this standard will ensure that containers are made to prevent leaks and spills protecting public health and the environment.

By understanding the types of storage tanks available and their applications, you can make informed decisions that enhance safety, ensure compliance, and optimize your operations. Selecting the right type of storage tank is crucial for maximizing efficiency and minimizing risks in any storage operation. Whether you’re in the fuel, chemical, or water storage industry, the right tank can make all the difference in maintaining operational integrity and safety.

With the right information at hand, you can confidently navigate the complexities of storage tank selection and management, ensuring that your operations run smoothly and efficiently.