Key Takeaways

- What are the advantages of bulk fuel delivery for fleets? They include better uptime and better control.

- Bulk fuel delivery can reduce off-route refuelling and improve daily scheduling.

- Fuel management deliveries can improve tracking, accountability, and planning.

- Reliability can improve when on-site fuel supply reduces dependence on stations.

- Cost savings often include time, labour, and reduced disruption, not only price.

Table of Contents

What Are The Advantages Of Bulk Fuel Delivery For Fleets

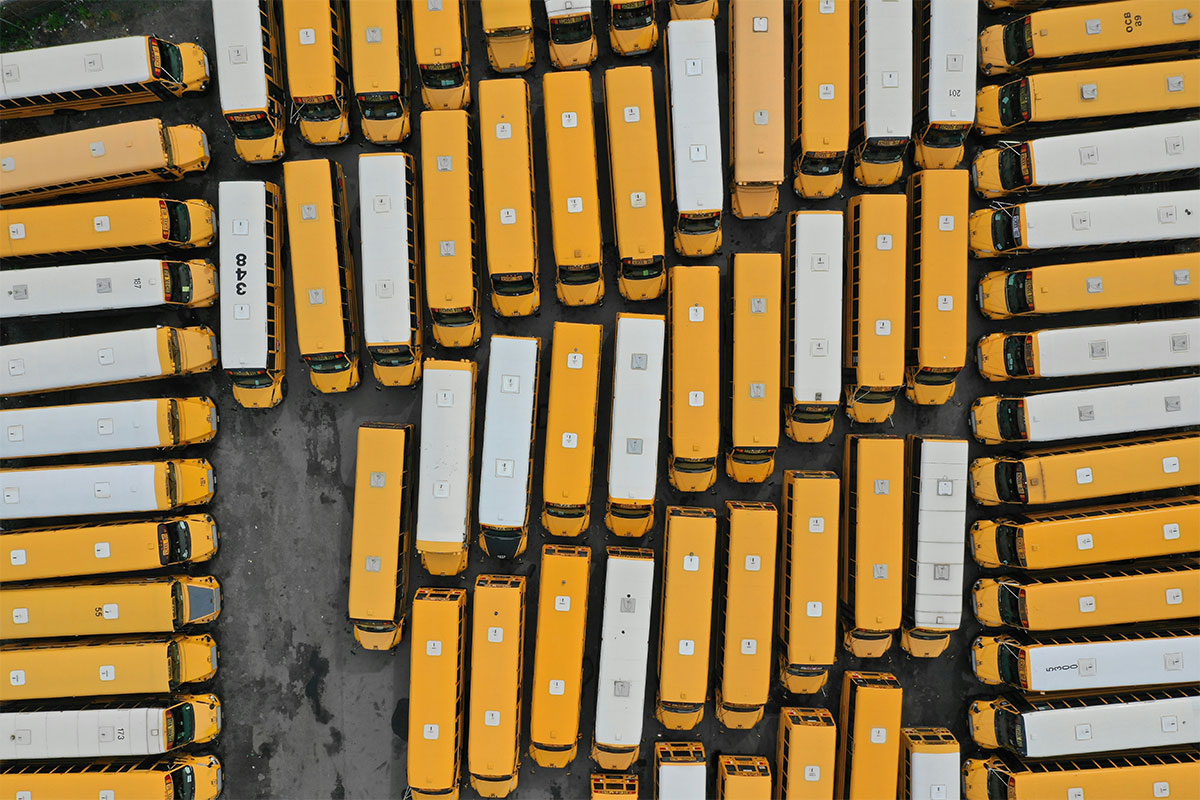

In a fleet context, bulk fuel delivery is the scheduled supply of fuel to a customer’s storage tank located at their yard, depot, or worksite. Vehicles and equipment refuel at this location, removing the need for retail stations. People also ask what is bulk fuel. It is fuel purchased in larger volumes for dedicated storage and dispensing, rather than bought one transaction at a time.

Fleets with consistent, measurable demand benefit significantly. When fuel usage is known, the supply plan can align with actual consumption and operating hours, which ensures consistency and control. This approach often results in fewer missed starts, fewer emergency refuel runs, and better tracking of fuel usage. Expectations for savings should be realistic. Benefits stem from a favorable price structure, reduced time and labor, and decreased operational disruption. Treating refueling as a planned process, not an unplanned stop, improves control and supports scalability as the fleet grows.

Strategic Value Of Bulk Fuel Delivery For Fleet Operations

Fuel strategy directly impacts competitiveness because fuel costs are involved in every trip and every hour of equipment use. Daily measurement of this cost allows for better decision-making. With bulk fuel delivery, fuel becomes a planned input instead of a reactive purchase. This makes it simpler to set targets and monitor performance.

Fuel is a controllable operating variable. Fleets can manage when and where vehicles refuel, and how usage is tracked. This control reduces waste and supports more accurate forecasting and consistent service. Drivers spending less time seeking fuel means easier schedule maintenance. Choosing a bulk supply is a long-term operational decision. It influences site layout, safety procedures, and supplier relationships. View it as a system supporting fleet growth, not just a one-time discount.

Why Businesses Turn To Bulk Fuel Delivery

Businesses usually switch after repeated operational pain points. Common reasons include these points.

- Drivers lose time leaving routes to find fuel and then returning to the route.

- Stations are far from the yard or the job site, which increases detours.

- Fuel spend is difficult to track by vehicle, driver, crew, or project.

- Growth increases volume and makes retail routines less workable.

- Reliability becomes critical during outages, weather disruptions, or supply constraints.

In many cases, the decision is about reliability and control. As fleet size and usage rise, small delays repeat many times. Bulk supply reduces those repeated losses when it is planned well.

How Bulk Fuel Delivery Transforms Large Operations

Large operations involve many moving parts, including more drivers, shifts, and sites. A delay for fuel in a single vehicle may be minor, but daily delays for dozens of vehicles create a significant impact. Bulk fuel delivery mitigates these delays by positioning the supply closer to where vehicles operate, park, or start.

Advantages based on scale increase with fleet size because coordination becomes the primary hurdle. Bulk supply facilitates standard refuel windows, consistent refuel locations, and shared procedures across various teams. It also assists multi-site operations in coordinating deliveries across multiple yards or job sites, which improves scheduling. Managers can then plan refuelling similarly to how they plan vehicle dispatch. Planning is often the most significant transformation, as fleets use a supply plan instead of reacting to low fuel warnings and station availability. This planning reduces unexpected stops and enhances dispatch efficiency, benefiting many industries that face common challenges with time loss and scheduling disruption.

Tired Of Losing Hours To Retail Fuel Stops?

Off-route refuelling adds detours, queues, and missed starts that repeat across the whole fleet. Move fuelling to your yard or job site and turn refuelling into a planned start of shift or end of shift routine that protects uptime and scheduling.

The Top Three Benefits Of Fleet Fuel Delivery

- Higher utilisation and fewer delays. Bulk fuel delivery can reduce time lost to retail stops and queues. Vehicles can start shifts fuelled and ready.

- Better control and clearer accountability. Bulk systems can support tracking by vehicle and by site, which reduces waste and supports better forecasting.

- More predictable operations. Planned supply reduces last-minute fuel runs and reduces exposure to station outages.

5 Key Advantages Of Fleet Fueling For Daily Operations

- Bulk fueling can make refuelling part of the normal start of shift or end of shift routine. Drivers refuel where they park, which reduces planning friction.

- On-site fuel supports early starts and late finishes when stations may be less convenient or less reliable. It also supports remote operations where stations are far away.

- On-site fuel can reduce missed starts caused by unexpected low fuel. It can also reduce disputes about when and where refuelling happened.

- Fuel management deliveries can support more accurate logs when paired with meter readings and driver identification. This improves accountability and supports cost control.

- Consistent on-site routines can improve safety. Refuelling happens in a planned area with clear rules, which reduces risky improvised refuelling.

Daily benefits come from predictability. Predictability reduces interruptions and helps managers plan the day with fewer surprises.

Need Better Control And Accountability Over Fuel Use?

Bulk delivery paired with on-site dispensing can help you track fuel by vehicle, driver, crew, or site, and spot fuel variance faster. With clearer logs, routine refuel windows, and fewer last-minute fuel runs, you get stronger forecasting and fewer disputes about when and where refuelling happened.

5 Ways Fleet Fueling Can Optimize Your Operations

To optimize your operations, follow the following tips;

- Match delivery frequency to real burn rates so tanks stay within safe and practical target ranges. This reduces runout risk and reduces emergency deliveries.

- Align refuelling windows with shift changes to reduce idle time and queuing. This can also support smoother dispatch and smoother route planning.

- Use vehicle-level usage tracking to identify outliers. Investigate causes such as idling, route changes, leakage, or misuse.

- Standardise refuelling steps across yards and sites. Standard steps reduce incidents and improve training outcomes.

- Coordinate supplier schedules with peak periods and planned downtime. This supports better access and reduces disruption when demand spikes.

Process optimization matters because it reduces friction. It also creates better data. Better data supports planning, budgeting, and performance management.

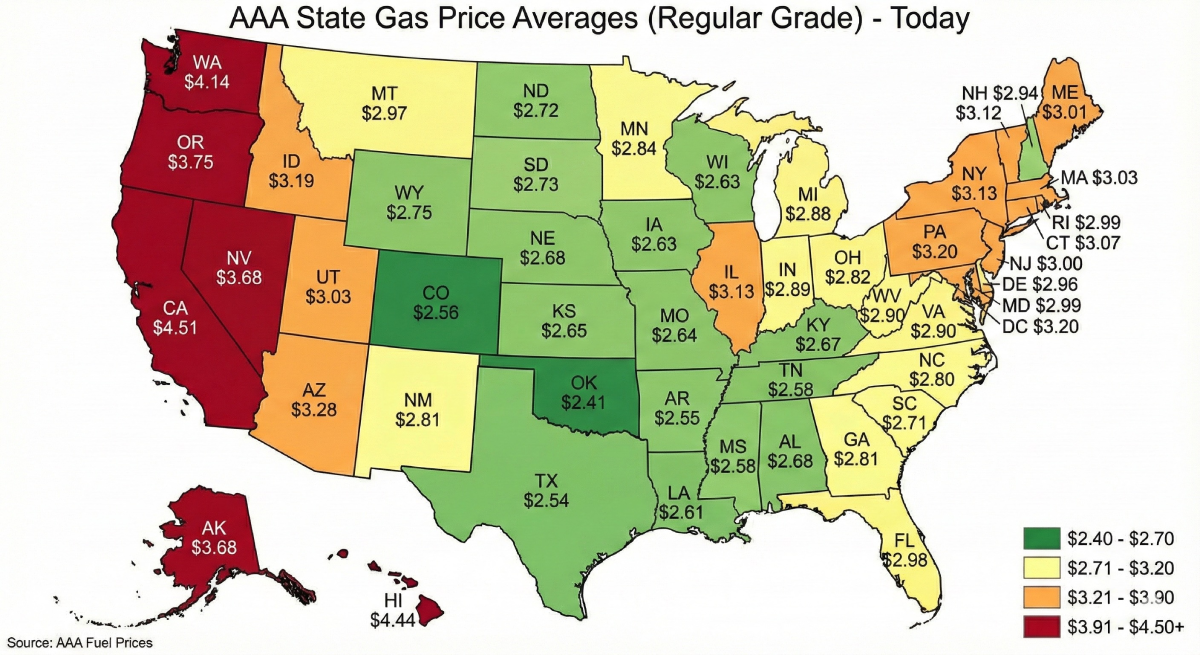

Is Buying Bulk Fuel Cheaper

Fleet managers often ask whether it is cheaper to buy gas in bulk. The accurate answer considers the total cost of ownership, not just the per-unit price. Retail prices include station overhead and convenience costs. Bulk supply involves storage and process controls. Indirect savings are significant. On-site refuelling reduces driver time, detours, mileage, wear, and delays. Bulk supply also improves cost predictability, reducing exposure to daily retail price swings and supporting stable budgeting.

A practical way to compare options is to lay out the main cost drivers as follows;

| Cost driver | Retail refuelling | Bulk fuel delivery |

|---|---|---|

| Driver time | Off-route stops are common | Yard refuel can be quicker |

| Detours and wear | Extra mileage adds cost | Less detour mileage |

| Visibility | Data depends on stations | Tank data can be more direct |

| Reliability | Exposure to outages and queues | On-site availability can be steadier |

| True cost | Price plus time plus disruption | Price plus storage plus controls |

The cheapest option is usually the one that reduces both fuel waste and time loss, while keeping supply reliable.

Saving Money With Wholesale Fuel Prices

Wholesale fuel pricing is determined by volume, delivery frequency, and local supply conditions. This highlights the importance of bulk fuel distribution. Suppliers generally utilize regional networks and optimize delivery routes for efficiency. The supply chain often includes fuel terminals where fuel is loaded for various delivery routes.

Long-term budgeting improves with predictable pricing and close usage tracking. Requesting a custom pricing quote from bulk fuel delivery companies is a helpful next step. Compare this quote to your current spending, including the cost of driver time, detours, and operational disruption. This comparison reliably shows potential savings for your specific fleet and usage pattern.

Cost Savings With Bulk Fuel Delivery

Savings result from multiple operational efficiencies, not just fuel price. Bulk fuel delivery reduces labor hours from retail stops, decreases mileage from detours, and lowers administrative time spent reconciling many small transactions. It also minimizes disruption when stations are crowded or unavailable. Measurable KPIs like refuelling time, fuel-related delays, detour mileage, and fuel variance show cost savings. Similarly, some light-duty fleets use bulk gasoline to improve predictability and reduce daily station dependence.

Cost Savings Of On Site Diesel Fuel Delivery

Diesel heavy fleets experience strong benefits because vehicles can refuel where they park. On-site fuel reduces the need for special refueling trips. This also minimizes moving equipment for fuel, protecting productive work hours. The total cost includes more than just the fuel price. It also covers the cost of time, idling, and moving equipment. On-site supply supports fleets that operate continuously, like construction, utility, and heavy haul operations. Proper planning ensures steadier uptime and simpler coordination.

Reduced Labor And Downtime

Retail refueling consumes time in small increments. A driver must leave the route, drive to a station, wait, refuel, and then return. In a large fleet, these small pieces of time accumulate significantly. bulk fuel delivery can mitigate this by ensuring fuel is available where vehicles are already located.

This approach yields labour efficiency gains in several ways. Drivers spend more time on their routes. Dispatchers experience fewer interruptions. Managers observe fewer last-minute fuel runs. Reducing downtime also improves productivity metrics. Fewer fuel-related delays increase on-time completion rates and reduce overtime caused by late returns. To measure downtime reduction, compare the before and after metrics. Track the time spent refueling per vehicle each week. Monitor fuel-related delays logged by dispatch. Measure route deviations for fuel stops. Even minor reductions generate meaningful savings at scale.

Want To Know If Bulk Fuel Is Cheaper For Your Fleet?

The real answer is total cost, not just price per gallon. Compare wholesale style pricing with the hidden costs of retail, including driver time, detour mileage, downtime, and admin reconciliation, then see what a delivery schedule matched to your burn rate would look like.

Construction Site Fuel Delivery

Construction site fuel delivery supports equipment uptime and simplifies site logistics. Continuous machine operation requires a steady fuel supply. Interruptions can delay project sequencing and slow overall progress. On-site supply reduces the need for external refuel trips, minimizing the risk of running short during a task. Coordinating deliveries with project timelines, site access rules, and work phases maximizes benefits. Well-planned supply supports higher equipment availability, fewer delays, and better planning for periods of peak site activity.

What Is Bulk Fuel Delivery

Bulk fuel delivery is the supply of fuel in large quantities to a customer’s on-site storage tank. The customer then dispenses the fuel directly to their vehicles or equipment. This process differs from retail refuelling because it involves a planned supply, storage, and controlled dispensing. People often ask what is bulk fuel. It is fuel purchased in larger volumes for storage and controlled use. This delivery method supports various fuel types, including diesel, bulk gasoline for service fleets, and propane through bulk gas delivery. Suppliers load fuel from fuel terminals and deliver it along planned routes. A strong supplier relationship ensures consistent scheduling and good communication during demand changes.

Improved Inventory Management And Fuel Monitoring

Bulk systems improve inventory management since fuel flows through known points. Metering tanks and identifying vehicles allow usage to be assigned to a unit, driver, crew, or project. This supports accountability and helps reduce waste. Monitoring also supports theft prevention. Unexpected drawdowns prompt fast investigation. Inventory practices prevent runouts. Planned thresholds and delivery schedules reduce emergency calls and minimize downtime from low supply. This is also where fuel management deliveries add value. Pairing delivery scheduling with monitoring helps fleets maintain stable inventory levels, which reduces disruption and supports smoother operations.

Most Effective Methods For Controlling Fuel Expenses In Fleet Operations

Fleets assess retail refuelling, fuel cards, and bulk fuel delivery. Retail offers flexibility but lacks control at scale. Fuel cards provide reporting, but drivers still spend time at stations and may face queues or outages. Bulk fuel delivery requires storage but significantly improves process control and data visibility. Control mechanisms are vital because accurate forecasting depends on good data. Bulk systems allow for authorised refuel windows, vehicle identification, and exception reporting. Over time, these controls reduce variance and support better planning. This is especially helpful for multi-site operations tracking fuel by site and project.

Additionally, bulk fuel delivery improves internal discipline. When refuelling is routine and recorded, enforcing policies and investigating anomalies becomes easier. This operational advantage is why larger fleets often transition to bulk systems as they expand.

Reliability And Accessibility

Reliability is a key advantage for critical fleets. Bulk fuel delivery minimizes exposure to station outages, local shortages, and traffic congestion. Having fuel on site ensures that operations can continue even when retail access is limited. Accessibility is vital for remote, night, and multi-site operations. Bulk supply supports these needs by keeping fuel near the work site. This reduces lost time from searching for stations or taking detours. Supplier capability is also important. Evaluate coverage, delivery capacity, communication, and contingency planning. Strong supply planning requires understanding local supply points like fuel terminals because terminal access can impact delivery timing during high-demand periods.